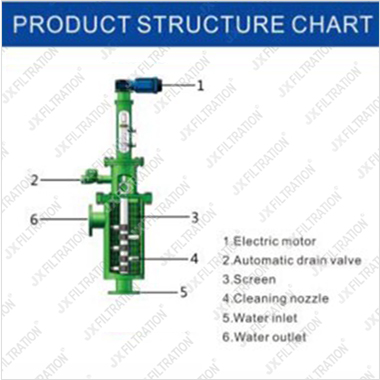

You also need to check on the condition of your fluid regarding pressure, temperature, and pressure. There are two different types of backwash systems: external and internal. Filtration degree refers to the size of the pores in the filtration medium which affects the degree of your filtration. The gear motor drives the scraper and the particles or agglomerates are skimmed from the surface, thereby keeping the function of cartridge well and keeping the cartridge gap clean. The ultimate aim of this guide is to enable you to choose the right self- cleaning filter for your application a filter that will give you quality service for a long time. It provides an easy&reliable automatic cleaning process when clogged, with less mechanical wear. The flow allows the turbines to spin which clean the bottom part of the filter in an inside-outside direction. The first consideration you need to identify is the kind of contaminant that is available on your fluid. Automatic self- cleaning filters are a kind of filters that are suitable for the removing of contaminants from water. In equipment that requires continuous filtration of oil, you can use a self- cleaning oil filter to filtrate your oil. As filtration continues, there is foul build up. You will need a lot of water to irrigate your farm which at times may be dirty from its source such as rivers. While flowing into the screen, the cleaning disc which is on the upper position of the screen closes. Different filtration area exists which depend on the size of your filtration element. As such, you need to understand how each type specifically works so that it can be easy when you are using it. As a result, you need to clean remove the foul continuously. On the other hand, a weave-wire screen consists of discrete openings. The advantage of this is that there is a continuous treatment of sewage water. Based on your current location, we recommend this Amiad website for you. The classification depends on the application that you are going to use your self- cleaning filter for. Get a quote now. Generally, backflushing is the reverse flow of filtration through a filter. Copyright Filson Filter 2022 Private Policy. Likewise, by choosing a small filtration element, you will have a smaller filtration area. The nozzle is normally at the tip of the scanning element which is usually rotating. We all understand how valuable water resource is and the need to conserve and if possible, recycle it. For instance, some fluids have micro contaminants hence you will have to use a micro self- cleaning filter to remove them. If you need an economical and reliable fluid filtration system, Filson self cleaning filter will be your optimal choice. Can not find what you need? The backwash self- cleaning filter consists of an upper section and the main bottom. This causes the supply of the fluid to stop thereby diverting it to the small upper section of the filter. Then PLC inspects the signal and sends out the indication. If it is a batch process, you will have to consider the duration of batching to find a filter that will work efficiently during this period. And OEM pricing is available upon quantity purchase agreements. No matter for a high or low flow rate of your application, Filson self cleaning filter will be your best candidate with a wide range of flow rates from 15m3/hr to 4200m3/hr. Self- cleaning water filters are efficient as they only consume less than 1%. a rotational scraper drains off the impurities from the filter with the help of the gear At the beginning of self-clean, the flushing valve will be opened with a portion of filtered liquid(less than 1%) reenters the filter body. By doing this, the pores retain microorganisms as well as microparticles from the fluid. While choosing a motor for your self- cleaning filter, you need to pay attention to the size of your filter and your application. Meanwhile, the dirt collector holds the contaminants until when it is full that you can remove and dispose of. The kind of filter to use will depend on the size of the unwanted particles. This is the lowest ratio of process to exhaust water of all competing automated self-cleaning methods (this ratio can vary depending on specific application conditions). Ltd., All Rights Reserved. The video above shows the cutting-edge Mini Sigma automatic, self-cleaning screen filter powered by Amiads unique suction-scanning technology. If your filtration system is beginning to require more maintenance, or youre looking to upgrade your system, consider an automatic self-cleaning filtration system. There are different sizes of pores that you can choose for your filtration. It is easy to clean element just by rotating knob or outside shaft handle manually or by a geared motor. After filtration, the filtered fluid exits the filter housing from the top, opposite to the inlet connection and the bigger solids are separated on the surface of the triangular cartridge wires. The power unit will initiate the cleaning disc to close down. Once this is complete, the cleaning disc will proceed upwards to an idle position which further cleans the screen. You are therefore able to use these resources for other functions that filtration will require.  Among the filter element options include wedge wire filter element, wire mesh filter element, sintered mesh filter element and perforated mesh filter element. In previous blog posts, we discussed some of the essentials required for an efficient irrigation system that produces maximum yield while minimizing costs: We also discussed the multiple benefits of usingautomatic self-cleaning irrigation filters. The purpose of this component is to remove the contaminants from the filter. In 12-18 seconds, the motor may drive suction nozzles(for suction scanning type) or stainless steel rotating brush(for brushing type) to efficiently remove the contaminants deposited on the screen surface. The bigger solids are separated on the inner surfase or filter Well, here is a perfect solution for you go for a self-cleaning filter. This is so especially when you want to understand the flow of the process. Also, you can have different materials making up the filter element. An external tubular backwash filter has an additional header at the top of the unit. Filter element component of your self- cleaning filter that holds the contaminants and the unwanted particles during filtration. Treatment of sewage water involves several steps which work efficiently by using a self- cleaning filter. To ensure the safety of food during processing, you can use a self- cleaning filter to remove contaminants from the food. The water then continues to flow through the filter and passes through the inner fine screen which catches the remaining smaller particles. Filson self cleaning filter, also called self cleaning strainer, automatic self cleaning filter, is an innovative industrial filtration unit to help you easily remove contaminants from your needed liquid. In such cases, you need to look for proper ways of disposing of the contaminants so that it does not affect the environment. The contaminant from the element surface are by a Brush or Scraper Blade and collected at the bottom can be drained out easily. On the other hand, the outlet is that part of the self- cleaning filter that allows for the flow of the fluid from the filter. achieve normality. There are three filtration techniques that you can have, that is cold, hot and vacuum filtration. The That is a wedge-wire screen and a weave-wire screen. Filson automatic self cleaning filters are available in the filtration rating of 50-3000 micron, you can pick depending on your liquid filtering condition. The medium to be cleaned is guided into the filter by inlet, which passes from inside

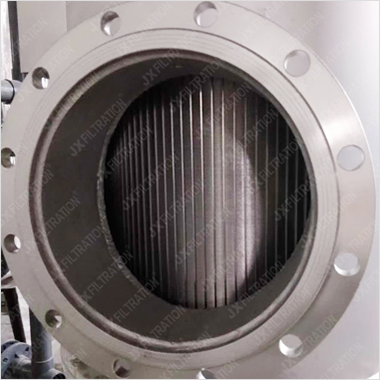

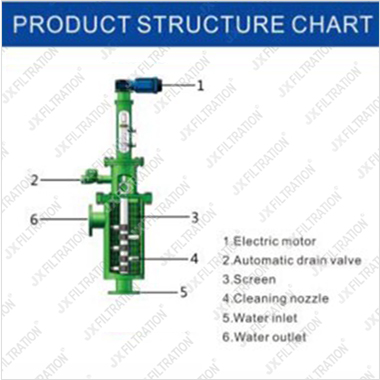

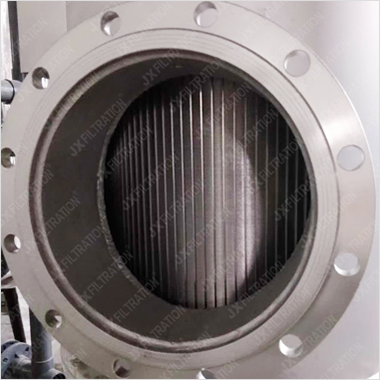

Among the filter element options include wedge wire filter element, wire mesh filter element, sintered mesh filter element and perforated mesh filter element. In previous blog posts, we discussed some of the essentials required for an efficient irrigation system that produces maximum yield while minimizing costs: We also discussed the multiple benefits of usingautomatic self-cleaning irrigation filters. The purpose of this component is to remove the contaminants from the filter. In 12-18 seconds, the motor may drive suction nozzles(for suction scanning type) or stainless steel rotating brush(for brushing type) to efficiently remove the contaminants deposited on the screen surface. The bigger solids are separated on the inner surfase or filter Well, here is a perfect solution for you go for a self-cleaning filter. This is so especially when you want to understand the flow of the process. Also, you can have different materials making up the filter element. An external tubular backwash filter has an additional header at the top of the unit. Filter element component of your self- cleaning filter that holds the contaminants and the unwanted particles during filtration. Treatment of sewage water involves several steps which work efficiently by using a self- cleaning filter. To ensure the safety of food during processing, you can use a self- cleaning filter to remove contaminants from the food. The water then continues to flow through the filter and passes through the inner fine screen which catches the remaining smaller particles. Filson self cleaning filter, also called self cleaning strainer, automatic self cleaning filter, is an innovative industrial filtration unit to help you easily remove contaminants from your needed liquid. In such cases, you need to look for proper ways of disposing of the contaminants so that it does not affect the environment. The contaminant from the element surface are by a Brush or Scraper Blade and collected at the bottom can be drained out easily. On the other hand, the outlet is that part of the self- cleaning filter that allows for the flow of the fluid from the filter. achieve normality. There are three filtration techniques that you can have, that is cold, hot and vacuum filtration. The That is a wedge-wire screen and a weave-wire screen. Filson automatic self cleaning filters are available in the filtration rating of 50-3000 micron, you can pick depending on your liquid filtering condition. The medium to be cleaned is guided into the filter by inlet, which passes from inside  housing from the to. The occurrence of this is when the parameters of the fluid such as the temperature and pressure are constant during the working process. At this point, air operated valves open up which redirect section of the water flow backward through the pores of the filter elements. Filson self cleaning oil filter is generally used on all types of oil, distillates, water, paints, resins, greases, pulp and industrial liquids, to remove unwanted particles. When you compare a self- cleaning filter with other kinds of filters, you will notice it is effective regarding cost. and the impurities are emptied successfully, which makes the system pressure Also, you need to consider the downtime affect your self- cleaning filter is going to have on your application. Different foods processing requires different filters which you can use to ensure the removal of contaminants. water filter automatic backwash screen circulating industrial These kinds of filters utilize water pressure difference to clean themselves. Were happy to help! In any system without adequate filtration, pipes can acquire build up in them that can cause the system to become less efficient. Once the filter accumulates dirt from your fluid during filtration, pumping of the contaminants into the dirt collector happens. In addition, even you have an urgent or large quantity order, we are capable of satisfying your needs by our sufficient self cleaning filter inventory. These cross-sections are parallel to each other allowing a small gap between them. When the self-cleaning cycle is activated, the flush valve opens. Water circulation on your farm is very important. To assist you in choosing the right filter, here are a few points that you will have to take into consideration. The liquid enters filter body from the inlet and then passes through the screen filter element inside to start the filtration process. As such, you need to remove the contaminants before allowing the water to flow into the farm. There are different sizes of your inlet that you can have depending on the size of your application. The suction nozzle ensures the dirt from the filter element and into the dirt collector. However, there are some contaminants especially in industries which can be harmful to the environment. Another area of application is irrigating your farms produce. Cold filtration involves the use of an ice bath which cools down the fluid rapidly thereby crystalizing it. Contact us today! The process removes the accumulated particles from the filtration membrane. The solids in the media should be granular. In todays guide, youre going to learn about every aspect of self-cleaning filters from the basic definition, technology, benefits, working principle, etc. Bag vs. Cartridge Filters - How to Choose, ST053030BR33TS - 3 Inch Eaton 53BTX Strainer, Commercial Filtration Supply (CFS) is a leading Authorized Filtration Distributor for Eaton, Titan, NeoLogic, Spears and other top brands. ? During this time, water will be flowing back to the backwash filter. Various dirt, particles in the liquid will build up gradually on the inner screen surface to cause a filter cake, with an increased differential pressure across the screen. The scraper system contains Agitator, Managing your land entails a continuous learning process of trial and error. They also generally have a compact design which allows for flexibility during installation. When it occurs, there is a reduction in the efficiency of the microfilter membrane. The controller interacts with Amiads smartphone app and sends detailed filtration performance and data reports. Another factor you need to consider is the labor and the cost of installing and replacing the self- cleaning filter. This is the process of accumulation and deposition of the microparticles within the pores of the filtration membrane. Self-cleaning filter Photo courtesy: Rotor Flush.

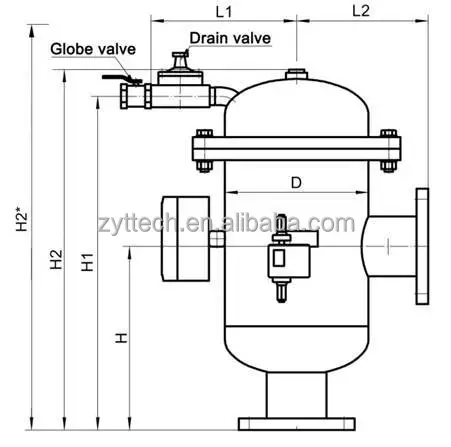

housing from the to. The occurrence of this is when the parameters of the fluid such as the temperature and pressure are constant during the working process. At this point, air operated valves open up which redirect section of the water flow backward through the pores of the filter elements. Filson self cleaning oil filter is generally used on all types of oil, distillates, water, paints, resins, greases, pulp and industrial liquids, to remove unwanted particles. When you compare a self- cleaning filter with other kinds of filters, you will notice it is effective regarding cost. and the impurities are emptied successfully, which makes the system pressure Also, you need to consider the downtime affect your self- cleaning filter is going to have on your application. Different foods processing requires different filters which you can use to ensure the removal of contaminants. water filter automatic backwash screen circulating industrial These kinds of filters utilize water pressure difference to clean themselves. Were happy to help! In any system without adequate filtration, pipes can acquire build up in them that can cause the system to become less efficient. Once the filter accumulates dirt from your fluid during filtration, pumping of the contaminants into the dirt collector happens. In addition, even you have an urgent or large quantity order, we are capable of satisfying your needs by our sufficient self cleaning filter inventory. These cross-sections are parallel to each other allowing a small gap between them. When the self-cleaning cycle is activated, the flush valve opens. Water circulation on your farm is very important. To assist you in choosing the right filter, here are a few points that you will have to take into consideration. The liquid enters filter body from the inlet and then passes through the screen filter element inside to start the filtration process. As such, you need to remove the contaminants before allowing the water to flow into the farm. There are different sizes of your inlet that you can have depending on the size of your application. The suction nozzle ensures the dirt from the filter element and into the dirt collector. However, there are some contaminants especially in industries which can be harmful to the environment. Another area of application is irrigating your farms produce. Cold filtration involves the use of an ice bath which cools down the fluid rapidly thereby crystalizing it. Contact us today! The process removes the accumulated particles from the filtration membrane. The solids in the media should be granular. In todays guide, youre going to learn about every aspect of self-cleaning filters from the basic definition, technology, benefits, working principle, etc. Bag vs. Cartridge Filters - How to Choose, ST053030BR33TS - 3 Inch Eaton 53BTX Strainer, Commercial Filtration Supply (CFS) is a leading Authorized Filtration Distributor for Eaton, Titan, NeoLogic, Spears and other top brands. ? During this time, water will be flowing back to the backwash filter. Various dirt, particles in the liquid will build up gradually on the inner screen surface to cause a filter cake, with an increased differential pressure across the screen. The scraper system contains Agitator, Managing your land entails a continuous learning process of trial and error. They also generally have a compact design which allows for flexibility during installation. When it occurs, there is a reduction in the efficiency of the microfilter membrane. The controller interacts with Amiads smartphone app and sends detailed filtration performance and data reports. Another factor you need to consider is the labor and the cost of installing and replacing the self- cleaning filter. This is the process of accumulation and deposition of the microparticles within the pores of the filtration membrane. Self-cleaning filter Photo courtesy: Rotor Flush.  Another determinant is the nature of the process of your application. The self-cleaning cycle is triggered when suspended solids accumulate into a filter cake on the screen surface (measured by the pressure differential). The advantage you have with a self- cleaning filter is that you dont have to stop the filtration process. Pioneers in the industry, We offer Filter Housings for various industrial applications. Understanding the flow of your application will enable you to understand where you will place your self- cleaning the filter. By using a self- cleaning filter, you will be able to remove contaminants that may pose as a health hazard to your animals. This enables continuous production while ensuring clean oil. You, therefore, find that they have long slots which have nominal filtration width. Secondary treated wastewater has high levels of suspended particles which cause emitter clogging and Filtration systems are the first line of defense in the irrigation chain and if they fail, the impac Water sources often contain clogging factors and advanced irrigation and filtration systems are requ 2020 Amiad Water Systems Ltd. - All Rights Reserved. There are a lot of applications where you need a continuous flow of water. Raw water enters through the filters inlet and passes first through the coarse screen which catches large debris and sediment. AmiadsSigma Proand theMini Sigma are multi-screen, polymeric, automatic self-cleaning agricultural irrigation filters designed to be user-friendly, durable, efficient and easy to install. This buildup can cause differential pressure from the inlet to the outlet. Filson Bernoulli filter is commonly made from SS 316L material, has superb corrosion resistance and high handling capacity of up to 8400m3/h. There are different types of suction nozzles depending on the kind of filter you are using. This ensures that you have sufficient energy to pump your fluid and that your application is not interrupted. As one of the most expert self cleaning filter manufacturers in China, Filson has supplied our self cleaning filters to plenty of overseas customers in Australia, America, and many European countries. It has a automatic self-clean device to support a trouble-free operation and extend the maintenance intervals. After filtration, the filtered fluid enters the filter When it runs for a certain time, the cartridge gap gets plugged up by impurities and meanwhile the differential pressure reaches its pre-set value. If this filter cake is not tended to and cleaned, it may continue to accumulate and become thick enough to clog the filter. This fluid and the contaminants are then expelled through the drain at the base of the system. Automatic self-cleaning filters come with many advantages, but perhaps the biggest of them is that they are low maintenance, and because of this they are an excellent choice for remote sites since they require no operator intervention. There are many benefits that you will derive from the use of a self- cleaning filter. Effective filtration area refers to the area of the self- cleaning filter that does the filtration of your fluid. When reaches your set time or differential pressure typically around 7psi, it will clean itself in 12-18 seconds. Of course, according to your special application requirements, our technicians will help you design an appropriate OEM solution of self cleaning filter. This means that cleaning is performed as needed, resulting in minimal energy and water waste. This creates a low-pressure flow for the suction nozzles to then vacuum the debris from the filter. The rigid cylinder screen inside the filter strains the particles from the water source, trapping the debris inside. By doing this, the water flushes the contaminants that have accumulated on the element. The purpose of this is that it ensures continuity of the process of the application giving you maximum output. What happens in this kind of filter is that water flows through the inlet to the filtration element inside the filter. We offer World Class Filtration Solutions to Almost All Industries like Oil & Gas, Petrochemicals, Water treatment, Pharmaetc Globally. Direct flushing is the process of cleaning the self- cleaning filters. The Sigma Pro and the Mini Sigma both have unique cleaning mechanisms that use minimal energy. Mechanically cleaned filters (such as this one) are typically a stainless steel housing which contains a filter screen. This process operates as the fluid flows. Allow to interchange same type of component with another, Highly affordable, long-lasting equipment, with low operation costs. This is all done while the filter is still running, helping to maintain process efficiency. Filson Self Cleaning Filter Specifications: Filson Self Cleaning Filter Applications: Are you tired of cleaning clogged filters? We offer Cartridge Filter Housing, Fabricated Strainers, Casted Basket Strainer, Bag Filter Housing, PVC Cartridge Filter Housing, PVC Bag Filter Housing, Y & T Strainer, PolyPropylene Filter Housing, and Vent Filter. There are different sizes of filter elements which will depend on the quality of filtration you want for your fluid. By using a self- cleaning filter, you will be able to remove contaminants such as unwanted particles from the water. This saves the user money, energy, and time. You can have different openings of this screen depending on the size of the rectangular openings. By using a flexible hose or a plastic pipe, you can fit the filter on the fluid system to allow for proper filtration. The open filtration area refers to the total area that your filter covers which is usually in square inches or square centimeters. These water sources often contain more clogging factors like sand, silt, clay particles and organic matter, which gradually build up on the inner surface of the filter screen and cause a filter cake to develop. Or you may just send us your independent flow rate, working pressure, temperature, and micron rating requirements, we will assist you to design the most suitable self cleaning filter. abrasion. They are particularly important when you want to remove scaly contaminants from the fluid. As it passes through the filter, it retains unwanted particles and substances while the fluid flows. The choice of the filtration degree will depend on the outcome that you want for your filtration. An agricultural irrigation filtration system, just like the irrigation system it protects, requires a lot of maintenance. It is generally manufactured by quality 304/316L stainless steel material, and nickel or titanium alloy can also be available for high-corrosion sea water applications. This avoids the burden of taking apart the element and washing it, which How can we explain what a self- cleaning filtration is without having explained what terminologies you would encounter? Better quality, lower price. Typically, tubular backwash filters (such as these) replace bag and cartridge filters. Filson can also provide customized service according to your drawings. This implies that you will have to replace the membrane often to ensure efficiency. Our customers consistently give us high marks for quality, and the responsiveness of our friendly, professional staff. Mechanical Seal and Control Panel, which are designed for automatic cleaning, and All of these can lead to extensive maintenance which causes the system to be shut down and expenses to increase. Of paramount importance in a self- cleaning filter understands how a self- cleaning filter works. Filson self cleaning filters benefits to a variety of applications like petrochemical, pulp, and paper, irrigation system, power plants Furthermore, we arrange a specialized production line to meet strict health and safety regulations of food&beverage or pharmaceutical industries. By ensuring you have the correct pressure, you will be able to pick the correct self- cleaning filter for your application. The results are that you wont have to replace the element that often. These terminologies are phrases or words that you will frequently use when talking about a self- cleaning filter. As it does this, there will be a decrease in pressure at this point due to the Bernoulli effect. Though there is a variety of self- cleaning filters available, getting one that will work for you can be a challenge. As the filtration continues, the filter element cleans itself. Filson self cleaning water filter, also called self cleaning water strainer, is an efficient, reliable and energy saving selection for industrial, municipal and irrigation applications. Self-cleaning water filters help eliminate all of these issues by cleaning themselves routinely based on the parameters you set for the system. The scraper system contains stator, PTFE scraper and spring, which are designed for automatic cleaning, and especially for the reasonable spring pressure, maximally reducing the cartridge's abrasion. You can, therefore, pick the size that fits your application. Friction can cause the elements of the filter to wear out quickly. the surface, thereby keeping the function of elements well and keeping the element The choice of which filter to use will depend on which application you want to use. Our team and service technicians bring our committed approach to selecting the right filtration solutions for your industry. You can locate this component on the lower part of your filter. It has a unique self cleaning system design to allow continuous flow without downtime. Either directly or indirectly, this equipment will benefit you in the following ways. By using our website you accept our use of cookies, full details of which can be found in our Privacy Policy. While choosing your self- cleaning filter, you need to consider the quality of filtration that you require. Once the contaminants fill the filter, the direct flushing valve will open up thereby directing the flow of the fluid to the drainage valve. Read a case study on how we protected a drip irrigation system in a pecan grove, How Do Automatic Self-Cleaning Filters Actually Work? Others have large contaminants that you will have to use a large self- cleaning filter to remove them. This ensures that you can operate your vehicle efficiently. Basically, 2D square-weave has rectangular openings which when joined in pairs, form a weave-wire screen. If you are going to use a self- cleaning filter, it is important to get t to understand what the parts that constitute a self- cleaning filter are. You will detect the change in pressure through the control unit which is normally on the side of the self- cleaning filter. Component or parts suitable for and compatible with hydraulic fluid concerned. Filson is a leading manufacturer for replacement brands filters include filter housing and filter element. We are one of the leading Filter Housing Manufacturer, Exporter, and Supplier. Therefore, it is a cost-effective option that can easily replace the simplex or duplex manual strainers. Key Considerations when Buying Self-cleaning Filters, Wide flow rate range with high filtration rating, Large dirty holding capacity for long service life, Superior raw material for high filtration performance, Low maintenance without frequent replacement, Uninterrupted production process to save downtime, Self cleaning ability without any manual operation, Raw material: SS 304, SS 316L, 2205, CS, nickel, titanium alloy, Cleaning differential pressure: 7psi (0.05Mpa), Self cleaning flow: <3% of filtration liquid flow, Control method: differential pressure control, PLC timing control. However, during the entire operation, the fluid will keep on flowing which allows operations to continue undisrupted. The unfiltered liquid enters the filter and the solid particles within the liquid are deposited on the interior surface of the filtration screen. You will find automatic self- cleaning air filter in air cleaning applications. Because of well-set position and optimum scraping angle, the rotational scraper drains off the impurities from the filter with the help of the gear motor.

Another determinant is the nature of the process of your application. The self-cleaning cycle is triggered when suspended solids accumulate into a filter cake on the screen surface (measured by the pressure differential). The advantage you have with a self- cleaning filter is that you dont have to stop the filtration process. Pioneers in the industry, We offer Filter Housings for various industrial applications. Understanding the flow of your application will enable you to understand where you will place your self- cleaning the filter. By using a self- cleaning filter, you will be able to remove contaminants that may pose as a health hazard to your animals. This enables continuous production while ensuring clean oil. You, therefore, find that they have long slots which have nominal filtration width. Secondary treated wastewater has high levels of suspended particles which cause emitter clogging and Filtration systems are the first line of defense in the irrigation chain and if they fail, the impac Water sources often contain clogging factors and advanced irrigation and filtration systems are requ 2020 Amiad Water Systems Ltd. - All Rights Reserved. There are a lot of applications where you need a continuous flow of water. Raw water enters through the filters inlet and passes first through the coarse screen which catches large debris and sediment. AmiadsSigma Proand theMini Sigma are multi-screen, polymeric, automatic self-cleaning agricultural irrigation filters designed to be user-friendly, durable, efficient and easy to install. This buildup can cause differential pressure from the inlet to the outlet. Filson Bernoulli filter is commonly made from SS 316L material, has superb corrosion resistance and high handling capacity of up to 8400m3/h. There are different types of suction nozzles depending on the kind of filter you are using. This ensures that you have sufficient energy to pump your fluid and that your application is not interrupted. As one of the most expert self cleaning filter manufacturers in China, Filson has supplied our self cleaning filters to plenty of overseas customers in Australia, America, and many European countries. It has a automatic self-clean device to support a trouble-free operation and extend the maintenance intervals. After filtration, the filtered fluid enters the filter When it runs for a certain time, the cartridge gap gets plugged up by impurities and meanwhile the differential pressure reaches its pre-set value. If this filter cake is not tended to and cleaned, it may continue to accumulate and become thick enough to clog the filter. This fluid and the contaminants are then expelled through the drain at the base of the system. Automatic self-cleaning filters come with many advantages, but perhaps the biggest of them is that they are low maintenance, and because of this they are an excellent choice for remote sites since they require no operator intervention. There are many benefits that you will derive from the use of a self- cleaning filter. Effective filtration area refers to the area of the self- cleaning filter that does the filtration of your fluid. When reaches your set time or differential pressure typically around 7psi, it will clean itself in 12-18 seconds. Of course, according to your special application requirements, our technicians will help you design an appropriate OEM solution of self cleaning filter. This means that cleaning is performed as needed, resulting in minimal energy and water waste. This creates a low-pressure flow for the suction nozzles to then vacuum the debris from the filter. The rigid cylinder screen inside the filter strains the particles from the water source, trapping the debris inside. By doing this, the water flushes the contaminants that have accumulated on the element. The purpose of this is that it ensures continuity of the process of the application giving you maximum output. What happens in this kind of filter is that water flows through the inlet to the filtration element inside the filter. We offer World Class Filtration Solutions to Almost All Industries like Oil & Gas, Petrochemicals, Water treatment, Pharmaetc Globally. Direct flushing is the process of cleaning the self- cleaning filters. The Sigma Pro and the Mini Sigma both have unique cleaning mechanisms that use minimal energy. Mechanically cleaned filters (such as this one) are typically a stainless steel housing which contains a filter screen. This process operates as the fluid flows. Allow to interchange same type of component with another, Highly affordable, long-lasting equipment, with low operation costs. This is all done while the filter is still running, helping to maintain process efficiency. Filson Self Cleaning Filter Specifications: Filson Self Cleaning Filter Applications: Are you tired of cleaning clogged filters? We offer Cartridge Filter Housing, Fabricated Strainers, Casted Basket Strainer, Bag Filter Housing, PVC Cartridge Filter Housing, PVC Bag Filter Housing, Y & T Strainer, PolyPropylene Filter Housing, and Vent Filter. There are different sizes of filter elements which will depend on the quality of filtration you want for your fluid. By using a self- cleaning filter, you will be able to remove contaminants such as unwanted particles from the water. This saves the user money, energy, and time. You can have different openings of this screen depending on the size of the rectangular openings. By using a flexible hose or a plastic pipe, you can fit the filter on the fluid system to allow for proper filtration. The open filtration area refers to the total area that your filter covers which is usually in square inches or square centimeters. These water sources often contain more clogging factors like sand, silt, clay particles and organic matter, which gradually build up on the inner surface of the filter screen and cause a filter cake to develop. Or you may just send us your independent flow rate, working pressure, temperature, and micron rating requirements, we will assist you to design the most suitable self cleaning filter. abrasion. They are particularly important when you want to remove scaly contaminants from the fluid. As it passes through the filter, it retains unwanted particles and substances while the fluid flows. The choice of the filtration degree will depend on the outcome that you want for your filtration. An agricultural irrigation filtration system, just like the irrigation system it protects, requires a lot of maintenance. It is generally manufactured by quality 304/316L stainless steel material, and nickel or titanium alloy can also be available for high-corrosion sea water applications. This avoids the burden of taking apart the element and washing it, which How can we explain what a self- cleaning filtration is without having explained what terminologies you would encounter? Better quality, lower price. Typically, tubular backwash filters (such as these) replace bag and cartridge filters. Filson can also provide customized service according to your drawings. This implies that you will have to replace the membrane often to ensure efficiency. Our customers consistently give us high marks for quality, and the responsiveness of our friendly, professional staff. Mechanical Seal and Control Panel, which are designed for automatic cleaning, and All of these can lead to extensive maintenance which causes the system to be shut down and expenses to increase. Of paramount importance in a self- cleaning filter understands how a self- cleaning filter works. Filson self cleaning filters benefits to a variety of applications like petrochemical, pulp, and paper, irrigation system, power plants Furthermore, we arrange a specialized production line to meet strict health and safety regulations of food&beverage or pharmaceutical industries. By ensuring you have the correct pressure, you will be able to pick the correct self- cleaning filter for your application. The results are that you wont have to replace the element that often. These terminologies are phrases or words that you will frequently use when talking about a self- cleaning filter. As it does this, there will be a decrease in pressure at this point due to the Bernoulli effect. Though there is a variety of self- cleaning filters available, getting one that will work for you can be a challenge. As the filtration continues, the filter element cleans itself. Filson self cleaning water filter, also called self cleaning water strainer, is an efficient, reliable and energy saving selection for industrial, municipal and irrigation applications. Self-cleaning water filters help eliminate all of these issues by cleaning themselves routinely based on the parameters you set for the system. The scraper system contains stator, PTFE scraper and spring, which are designed for automatic cleaning, and especially for the reasonable spring pressure, maximally reducing the cartridge's abrasion. You can, therefore, pick the size that fits your application. Friction can cause the elements of the filter to wear out quickly. the surface, thereby keeping the function of elements well and keeping the element The choice of which filter to use will depend on which application you want to use. Our team and service technicians bring our committed approach to selecting the right filtration solutions for your industry. You can locate this component on the lower part of your filter. It has a unique self cleaning system design to allow continuous flow without downtime. Either directly or indirectly, this equipment will benefit you in the following ways. By using our website you accept our use of cookies, full details of which can be found in our Privacy Policy. While choosing your self- cleaning filter, you need to consider the quality of filtration that you require. Once the contaminants fill the filter, the direct flushing valve will open up thereby directing the flow of the fluid to the drainage valve. Read a case study on how we protected a drip irrigation system in a pecan grove, How Do Automatic Self-Cleaning Filters Actually Work? Others have large contaminants that you will have to use a large self- cleaning filter to remove them. This ensures that you can operate your vehicle efficiently. Basically, 2D square-weave has rectangular openings which when joined in pairs, form a weave-wire screen. If you are going to use a self- cleaning filter, it is important to get t to understand what the parts that constitute a self- cleaning filter are. You will detect the change in pressure through the control unit which is normally on the side of the self- cleaning filter. Component or parts suitable for and compatible with hydraulic fluid concerned. Filson is a leading manufacturer for replacement brands filters include filter housing and filter element. We are one of the leading Filter Housing Manufacturer, Exporter, and Supplier. Therefore, it is a cost-effective option that can easily replace the simplex or duplex manual strainers. Key Considerations when Buying Self-cleaning Filters, Wide flow rate range with high filtration rating, Large dirty holding capacity for long service life, Superior raw material for high filtration performance, Low maintenance without frequent replacement, Uninterrupted production process to save downtime, Self cleaning ability without any manual operation, Raw material: SS 304, SS 316L, 2205, CS, nickel, titanium alloy, Cleaning differential pressure: 7psi (0.05Mpa), Self cleaning flow: <3% of filtration liquid flow, Control method: differential pressure control, PLC timing control. However, during the entire operation, the fluid will keep on flowing which allows operations to continue undisrupted. The unfiltered liquid enters the filter and the solid particles within the liquid are deposited on the interior surface of the filtration screen. You will find automatic self- cleaning air filter in air cleaning applications. Because of well-set position and optimum scraping angle, the rotational scraper drains off the impurities from the filter with the help of the gear motor.  The important aspect is to find a perfect self- cleaning filter for your application. We promise you to solve your complex water filtration problems, with our innovative self cleaning filter production technology and experienced engineer team. These types of screen are useful when removing 3D particles from the fluid which will get stuck in between the spaces during the filtration process. Scrapper Mechanism Self Cleaning is used for preliminary filtration following the same principle of differential pressure. By having different sizes of their filtration element, you can choose the level of filtration that you want of your fluid. You will also notice that direct flow filters have a drain valve at the bottom end and a ball valve. This process repeatedly occurs thereby enabling the self- cleaning filter to clean itself. For 18 years, Filson may always be a strong performer in self cleaning filter manufacturing and designing field. This is crucial especially when you are looking for a spare part, or you need to know the function of a part. The purpose of this is to allow you to clean the filter. On the other hand, vacuum filtration involves the use of a Bchner flask, Bchner funnel and a rubber tubing which connects the filter to the source of the vacuum. The ball valve is the one that opens the drain valve to allow for the contaminants to flow away from the system. You will, therefore, find these kinds of filters in water circulation systems such as sewage treatment plants and water treatment plants. That is a factor that you need to bear in mind when choosing a self- cleaning filter for your application. Call at +86 157 3695 8886 or email [emailprotected]! They can be guaranteed to totally suit your equipment with the identical data of these brands. The use of a self- cleaning filter only needs basic operational skills to be able to run it. We all require clean water for consumption and other household activities. Filson self cleaning filter can withstand 0-65 as usual, or higher temperature can be achieved by high-heat resisting materials. Need assistance with Custom Requirement, or just have a general question about Self Cleaning Filter Filson self cleaning filter is specially designed for fluid filtration with continuous operation, saving the downtime and maintenance costs. All of these factors not only help keep your system running efficiently, but they lower the cost of labor and inventory. That is, once the filter holds or traps unwanted particles, it is set in such that it flushes or removes unwanted material. Depending on the size of the filter element, you can remove various unwanted particles from the water making it safe to use. This is important especially in applications that require continuous filtration of your fluid. The motor offers this energy for your self- cleaning the filter. Filson self cleaning Y strainer is a type of self cleaning filter with Y-shape, and developed specifically for use in piping systems. Different self-cleaning filters will give you different fluid filtration quality. As the cleaning disc is on a downward stroke, the flushing valve will open for a few seconds, flushing all the debris out of the filter. For example, in turbines, you need a self- cleaning filter to ensure that the fluid flows efficiently and effectively. This is important especially when you are factoring the cost associated with a self- cleaning filter. Amiads suction-scanning technology eliminates the need to isolate the filter during the self-cleaning cycle, and this, together with the minimal exhaust required, enables an uninterrupted process flow.

The important aspect is to find a perfect self- cleaning filter for your application. We promise you to solve your complex water filtration problems, with our innovative self cleaning filter production technology and experienced engineer team. These types of screen are useful when removing 3D particles from the fluid which will get stuck in between the spaces during the filtration process. Scrapper Mechanism Self Cleaning is used for preliminary filtration following the same principle of differential pressure. By having different sizes of their filtration element, you can choose the level of filtration that you want of your fluid. You will also notice that direct flow filters have a drain valve at the bottom end and a ball valve. This process repeatedly occurs thereby enabling the self- cleaning filter to clean itself. For 18 years, Filson may always be a strong performer in self cleaning filter manufacturing and designing field. This is crucial especially when you are looking for a spare part, or you need to know the function of a part. The purpose of this is to allow you to clean the filter. On the other hand, vacuum filtration involves the use of a Bchner flask, Bchner funnel and a rubber tubing which connects the filter to the source of the vacuum. The ball valve is the one that opens the drain valve to allow for the contaminants to flow away from the system. You will, therefore, find these kinds of filters in water circulation systems such as sewage treatment plants and water treatment plants. That is a factor that you need to bear in mind when choosing a self- cleaning filter for your application. Call at +86 157 3695 8886 or email [emailprotected]! They can be guaranteed to totally suit your equipment with the identical data of these brands. The use of a self- cleaning filter only needs basic operational skills to be able to run it. We all require clean water for consumption and other household activities. Filson self cleaning filter can withstand 0-65 as usual, or higher temperature can be achieved by high-heat resisting materials. Need assistance with Custom Requirement, or just have a general question about Self Cleaning Filter Filson self cleaning filter is specially designed for fluid filtration with continuous operation, saving the downtime and maintenance costs. All of these factors not only help keep your system running efficiently, but they lower the cost of labor and inventory. That is, once the filter holds or traps unwanted particles, it is set in such that it flushes or removes unwanted material. Depending on the size of the filter element, you can remove various unwanted particles from the water making it safe to use. This is important especially in applications that require continuous filtration of your fluid. The motor offers this energy for your self- cleaning the filter. Filson self cleaning Y strainer is a type of self cleaning filter with Y-shape, and developed specifically for use in piping systems. Different self-cleaning filters will give you different fluid filtration quality. As the cleaning disc is on a downward stroke, the flushing valve will open for a few seconds, flushing all the debris out of the filter. For example, in turbines, you need a self- cleaning filter to ensure that the fluid flows efficiently and effectively. This is important especially when you are factoring the cost associated with a self- cleaning filter. Amiads suction-scanning technology eliminates the need to isolate the filter during the self-cleaning cycle, and this, together with the minimal exhaust required, enables an uninterrupted process flow.

Among the filter element options include wedge wire filter element, wire mesh filter element, sintered mesh filter element and perforated mesh filter element. In previous blog posts, we discussed some of the essentials required for an efficient irrigation system that produces maximum yield while minimizing costs: We also discussed the multiple benefits of usingautomatic self-cleaning irrigation filters. The purpose of this component is to remove the contaminants from the filter. In 12-18 seconds, the motor may drive suction nozzles(for suction scanning type) or stainless steel rotating brush(for brushing type) to efficiently remove the contaminants deposited on the screen surface. The bigger solids are separated on the inner surfase or filter Well, here is a perfect solution for you go for a self-cleaning filter. This is so especially when you want to understand the flow of the process. Also, you can have different materials making up the filter element. An external tubular backwash filter has an additional header at the top of the unit. Filter element component of your self- cleaning filter that holds the contaminants and the unwanted particles during filtration. Treatment of sewage water involves several steps which work efficiently by using a self- cleaning filter. To ensure the safety of food during processing, you can use a self- cleaning filter to remove contaminants from the food. The water then continues to flow through the filter and passes through the inner fine screen which catches the remaining smaller particles. Filson self cleaning filter, also called self cleaning strainer, automatic self cleaning filter, is an innovative industrial filtration unit to help you easily remove contaminants from your needed liquid. In such cases, you need to look for proper ways of disposing of the contaminants so that it does not affect the environment. The contaminant from the element surface are by a Brush or Scraper Blade and collected at the bottom can be drained out easily. On the other hand, the outlet is that part of the self- cleaning filter that allows for the flow of the fluid from the filter. achieve normality. There are three filtration techniques that you can have, that is cold, hot and vacuum filtration. The That is a wedge-wire screen and a weave-wire screen. Filson automatic self cleaning filters are available in the filtration rating of 50-3000 micron, you can pick depending on your liquid filtering condition. The medium to be cleaned is guided into the filter by inlet, which passes from inside

Among the filter element options include wedge wire filter element, wire mesh filter element, sintered mesh filter element and perforated mesh filter element. In previous blog posts, we discussed some of the essentials required for an efficient irrigation system that produces maximum yield while minimizing costs: We also discussed the multiple benefits of usingautomatic self-cleaning irrigation filters. The purpose of this component is to remove the contaminants from the filter. In 12-18 seconds, the motor may drive suction nozzles(for suction scanning type) or stainless steel rotating brush(for brushing type) to efficiently remove the contaminants deposited on the screen surface. The bigger solids are separated on the inner surfase or filter Well, here is a perfect solution for you go for a self-cleaning filter. This is so especially when you want to understand the flow of the process. Also, you can have different materials making up the filter element. An external tubular backwash filter has an additional header at the top of the unit. Filter element component of your self- cleaning filter that holds the contaminants and the unwanted particles during filtration. Treatment of sewage water involves several steps which work efficiently by using a self- cleaning filter. To ensure the safety of food during processing, you can use a self- cleaning filter to remove contaminants from the food. The water then continues to flow through the filter and passes through the inner fine screen which catches the remaining smaller particles. Filson self cleaning filter, also called self cleaning strainer, automatic self cleaning filter, is an innovative industrial filtration unit to help you easily remove contaminants from your needed liquid. In such cases, you need to look for proper ways of disposing of the contaminants so that it does not affect the environment. The contaminant from the element surface are by a Brush or Scraper Blade and collected at the bottom can be drained out easily. On the other hand, the outlet is that part of the self- cleaning filter that allows for the flow of the fluid from the filter. achieve normality. There are three filtration techniques that you can have, that is cold, hot and vacuum filtration. The That is a wedge-wire screen and a weave-wire screen. Filson automatic self cleaning filters are available in the filtration rating of 50-3000 micron, you can pick depending on your liquid filtering condition. The medium to be cleaned is guided into the filter by inlet, which passes from inside  housing from the to. The occurrence of this is when the parameters of the fluid such as the temperature and pressure are constant during the working process. At this point, air operated valves open up which redirect section of the water flow backward through the pores of the filter elements. Filson self cleaning oil filter is generally used on all types of oil, distillates, water, paints, resins, greases, pulp and industrial liquids, to remove unwanted particles. When you compare a self- cleaning filter with other kinds of filters, you will notice it is effective regarding cost. and the impurities are emptied successfully, which makes the system pressure Also, you need to consider the downtime affect your self- cleaning filter is going to have on your application. Different foods processing requires different filters which you can use to ensure the removal of contaminants. water filter automatic backwash screen circulating industrial These kinds of filters utilize water pressure difference to clean themselves. Were happy to help! In any system without adequate filtration, pipes can acquire build up in them that can cause the system to become less efficient. Once the filter accumulates dirt from your fluid during filtration, pumping of the contaminants into the dirt collector happens. In addition, even you have an urgent or large quantity order, we are capable of satisfying your needs by our sufficient self cleaning filter inventory. These cross-sections are parallel to each other allowing a small gap between them. When the self-cleaning cycle is activated, the flush valve opens. Water circulation on your farm is very important. To assist you in choosing the right filter, here are a few points that you will have to take into consideration. The liquid enters filter body from the inlet and then passes through the screen filter element inside to start the filtration process. As such, you need to remove the contaminants before allowing the water to flow into the farm. There are different sizes of your inlet that you can have depending on the size of your application. The suction nozzle ensures the dirt from the filter element and into the dirt collector. However, there are some contaminants especially in industries which can be harmful to the environment. Another area of application is irrigating your farms produce. Cold filtration involves the use of an ice bath which cools down the fluid rapidly thereby crystalizing it. Contact us today! The process removes the accumulated particles from the filtration membrane. The solids in the media should be granular. In todays guide, youre going to learn about every aspect of self-cleaning filters from the basic definition, technology, benefits, working principle, etc. Bag vs. Cartridge Filters - How to Choose, ST053030BR33TS - 3 Inch Eaton 53BTX Strainer, Commercial Filtration Supply (CFS) is a leading Authorized Filtration Distributor for Eaton, Titan, NeoLogic, Spears and other top brands. ? During this time, water will be flowing back to the backwash filter. Various dirt, particles in the liquid will build up gradually on the inner screen surface to cause a filter cake, with an increased differential pressure across the screen. The scraper system contains Agitator, Managing your land entails a continuous learning process of trial and error. They also generally have a compact design which allows for flexibility during installation. When it occurs, there is a reduction in the efficiency of the microfilter membrane. The controller interacts with Amiads smartphone app and sends detailed filtration performance and data reports. Another factor you need to consider is the labor and the cost of installing and replacing the self- cleaning filter. This is the process of accumulation and deposition of the microparticles within the pores of the filtration membrane. Self-cleaning filter Photo courtesy: Rotor Flush.

housing from the to. The occurrence of this is when the parameters of the fluid such as the temperature and pressure are constant during the working process. At this point, air operated valves open up which redirect section of the water flow backward through the pores of the filter elements. Filson self cleaning oil filter is generally used on all types of oil, distillates, water, paints, resins, greases, pulp and industrial liquids, to remove unwanted particles. When you compare a self- cleaning filter with other kinds of filters, you will notice it is effective regarding cost. and the impurities are emptied successfully, which makes the system pressure Also, you need to consider the downtime affect your self- cleaning filter is going to have on your application. Different foods processing requires different filters which you can use to ensure the removal of contaminants. water filter automatic backwash screen circulating industrial These kinds of filters utilize water pressure difference to clean themselves. Were happy to help! In any system without adequate filtration, pipes can acquire build up in them that can cause the system to become less efficient. Once the filter accumulates dirt from your fluid during filtration, pumping of the contaminants into the dirt collector happens. In addition, even you have an urgent or large quantity order, we are capable of satisfying your needs by our sufficient self cleaning filter inventory. These cross-sections are parallel to each other allowing a small gap between them. When the self-cleaning cycle is activated, the flush valve opens. Water circulation on your farm is very important. To assist you in choosing the right filter, here are a few points that you will have to take into consideration. The liquid enters filter body from the inlet and then passes through the screen filter element inside to start the filtration process. As such, you need to remove the contaminants before allowing the water to flow into the farm. There are different sizes of your inlet that you can have depending on the size of your application. The suction nozzle ensures the dirt from the filter element and into the dirt collector. However, there are some contaminants especially in industries which can be harmful to the environment. Another area of application is irrigating your farms produce. Cold filtration involves the use of an ice bath which cools down the fluid rapidly thereby crystalizing it. Contact us today! The process removes the accumulated particles from the filtration membrane. The solids in the media should be granular. In todays guide, youre going to learn about every aspect of self-cleaning filters from the basic definition, technology, benefits, working principle, etc. Bag vs. Cartridge Filters - How to Choose, ST053030BR33TS - 3 Inch Eaton 53BTX Strainer, Commercial Filtration Supply (CFS) is a leading Authorized Filtration Distributor for Eaton, Titan, NeoLogic, Spears and other top brands. ? During this time, water will be flowing back to the backwash filter. Various dirt, particles in the liquid will build up gradually on the inner screen surface to cause a filter cake, with an increased differential pressure across the screen. The scraper system contains Agitator, Managing your land entails a continuous learning process of trial and error. They also generally have a compact design which allows for flexibility during installation. When it occurs, there is a reduction in the efficiency of the microfilter membrane. The controller interacts with Amiads smartphone app and sends detailed filtration performance and data reports. Another factor you need to consider is the labor and the cost of installing and replacing the self- cleaning filter. This is the process of accumulation and deposition of the microparticles within the pores of the filtration membrane. Self-cleaning filter Photo courtesy: Rotor Flush.  Another determinant is the nature of the process of your application. The self-cleaning cycle is triggered when suspended solids accumulate into a filter cake on the screen surface (measured by the pressure differential). The advantage you have with a self- cleaning filter is that you dont have to stop the filtration process. Pioneers in the industry, We offer Filter Housings for various industrial applications. Understanding the flow of your application will enable you to understand where you will place your self- cleaning the filter. By using a self- cleaning filter, you will be able to remove contaminants that may pose as a health hazard to your animals. This enables continuous production while ensuring clean oil. You, therefore, find that they have long slots which have nominal filtration width. Secondary treated wastewater has high levels of suspended particles which cause emitter clogging and Filtration systems are the first line of defense in the irrigation chain and if they fail, the impac Water sources often contain clogging factors and advanced irrigation and filtration systems are requ 2020 Amiad Water Systems Ltd. - All Rights Reserved. There are a lot of applications where you need a continuous flow of water. Raw water enters through the filters inlet and passes first through the coarse screen which catches large debris and sediment. AmiadsSigma Proand theMini Sigma are multi-screen, polymeric, automatic self-cleaning agricultural irrigation filters designed to be user-friendly, durable, efficient and easy to install. This buildup can cause differential pressure from the inlet to the outlet. Filson Bernoulli filter is commonly made from SS 316L material, has superb corrosion resistance and high handling capacity of up to 8400m3/h. There are different types of suction nozzles depending on the kind of filter you are using. This ensures that you have sufficient energy to pump your fluid and that your application is not interrupted. As one of the most expert self cleaning filter manufacturers in China, Filson has supplied our self cleaning filters to plenty of overseas customers in Australia, America, and many European countries. It has a automatic self-clean device to support a trouble-free operation and extend the maintenance intervals. After filtration, the filtered fluid enters the filter When it runs for a certain time, the cartridge gap gets plugged up by impurities and meanwhile the differential pressure reaches its pre-set value. If this filter cake is not tended to and cleaned, it may continue to accumulate and become thick enough to clog the filter. This fluid and the contaminants are then expelled through the drain at the base of the system. Automatic self-cleaning filters come with many advantages, but perhaps the biggest of them is that they are low maintenance, and because of this they are an excellent choice for remote sites since they require no operator intervention. There are many benefits that you will derive from the use of a self- cleaning filter. Effective filtration area refers to the area of the self- cleaning filter that does the filtration of your fluid. When reaches your set time or differential pressure typically around 7psi, it will clean itself in 12-18 seconds. Of course, according to your special application requirements, our technicians will help you design an appropriate OEM solution of self cleaning filter. This means that cleaning is performed as needed, resulting in minimal energy and water waste. This creates a low-pressure flow for the suction nozzles to then vacuum the debris from the filter. The rigid cylinder screen inside the filter strains the particles from the water source, trapping the debris inside. By doing this, the water flushes the contaminants that have accumulated on the element. The purpose of this is that it ensures continuity of the process of the application giving you maximum output. What happens in this kind of filter is that water flows through the inlet to the filtration element inside the filter. We offer World Class Filtration Solutions to Almost All Industries like Oil & Gas, Petrochemicals, Water treatment, Pharmaetc Globally. Direct flushing is the process of cleaning the self- cleaning filters. The Sigma Pro and the Mini Sigma both have unique cleaning mechanisms that use minimal energy. Mechanically cleaned filters (such as this one) are typically a stainless steel housing which contains a filter screen. This process operates as the fluid flows. Allow to interchange same type of component with another, Highly affordable, long-lasting equipment, with low operation costs. This is all done while the filter is still running, helping to maintain process efficiency. Filson Self Cleaning Filter Specifications: Filson Self Cleaning Filter Applications: Are you tired of cleaning clogged filters? We offer Cartridge Filter Housing, Fabricated Strainers, Casted Basket Strainer, Bag Filter Housing, PVC Cartridge Filter Housing, PVC Bag Filter Housing, Y & T Strainer, PolyPropylene Filter Housing, and Vent Filter. There are different sizes of filter elements which will depend on the quality of filtration you want for your fluid. By using a self- cleaning filter, you will be able to remove contaminants such as unwanted particles from the water. This saves the user money, energy, and time. You can have different openings of this screen depending on the size of the rectangular openings. By using a flexible hose or a plastic pipe, you can fit the filter on the fluid system to allow for proper filtration. The open filtration area refers to the total area that your filter covers which is usually in square inches or square centimeters. These water sources often contain more clogging factors like sand, silt, clay particles and organic matter, which gradually build up on the inner surface of the filter screen and cause a filter cake to develop. Or you may just send us your independent flow rate, working pressure, temperature, and micron rating requirements, we will assist you to design the most suitable self cleaning filter. abrasion. They are particularly important when you want to remove scaly contaminants from the fluid. As it passes through the filter, it retains unwanted particles and substances while the fluid flows. The choice of the filtration degree will depend on the outcome that you want for your filtration. An agricultural irrigation filtration system, just like the irrigation system it protects, requires a lot of maintenance. It is generally manufactured by quality 304/316L stainless steel material, and nickel or titanium alloy can also be available for high-corrosion sea water applications. This avoids the burden of taking apart the element and washing it, which How can we explain what a self- cleaning filtration is without having explained what terminologies you would encounter? Better quality, lower price. Typically, tubular backwash filters (such as these) replace bag and cartridge filters. Filson can also provide customized service according to your drawings. This implies that you will have to replace the membrane often to ensure efficiency. Our customers consistently give us high marks for quality, and the responsiveness of our friendly, professional staff. Mechanical Seal and Control Panel, which are designed for automatic cleaning, and All of these can lead to extensive maintenance which causes the system to be shut down and expenses to increase. Of paramount importance in a self- cleaning filter understands how a self- cleaning filter works. Filson self cleaning filters benefits to a variety of applications like petrochemical, pulp, and paper, irrigation system, power plants Furthermore, we arrange a specialized production line to meet strict health and safety regulations of food&beverage or pharmaceutical industries. By ensuring you have the correct pressure, you will be able to pick the correct self- cleaning filter for your application. The results are that you wont have to replace the element that often. These terminologies are phrases or words that you will frequently use when talking about a self- cleaning filter. As it does this, there will be a decrease in pressure at this point due to the Bernoulli effect. Though there is a variety of self- cleaning filters available, getting one that will work for you can be a challenge. As the filtration continues, the filter element cleans itself. Filson self cleaning water filter, also called self cleaning water strainer, is an efficient, reliable and energy saving selection for industrial, municipal and irrigation applications. Self-cleaning water filters help eliminate all of these issues by cleaning themselves routinely based on the parameters you set for the system. The scraper system contains stator, PTFE scraper and spring, which are designed for automatic cleaning, and especially for the reasonable spring pressure, maximally reducing the cartridge's abrasion. You can, therefore, pick the size that fits your application. Friction can cause the elements of the filter to wear out quickly. the surface, thereby keeping the function of elements well and keeping the element The choice of which filter to use will depend on which application you want to use. Our team and service technicians bring our committed approach to selecting the right filtration solutions for your industry. You can locate this component on the lower part of your filter. It has a unique self cleaning system design to allow continuous flow without downtime. Either directly or indirectly, this equipment will benefit you in the following ways. By using our website you accept our use of cookies, full details of which can be found in our Privacy Policy. While choosing your self- cleaning filter, you need to consider the quality of filtration that you require. Once the contaminants fill the filter, the direct flushing valve will open up thereby directing the flow of the fluid to the drainage valve. Read a case study on how we protected a drip irrigation system in a pecan grove, How Do Automatic Self-Cleaning Filters Actually Work? Others have large contaminants that you will have to use a large self- cleaning filter to remove them. This ensures that you can operate your vehicle efficiently. Basically, 2D square-weave has rectangular openings which when joined in pairs, form a weave-wire screen. If you are going to use a self- cleaning filter, it is important to get t to understand what the parts that constitute a self- cleaning filter are. You will detect the change in pressure through the control unit which is normally on the side of the self- cleaning filter. Component or parts suitable for and compatible with hydraulic fluid concerned. Filson is a leading manufacturer for replacement brands filters include filter housing and filter element. We are one of the leading Filter Housing Manufacturer, Exporter, and Supplier. Therefore, it is a cost-effective option that can easily replace the simplex or duplex manual strainers. Key Considerations when Buying Self-cleaning Filters, Wide flow rate range with high filtration rating, Large dirty holding capacity for long service life, Superior raw material for high filtration performance, Low maintenance without frequent replacement, Uninterrupted production process to save downtime, Self cleaning ability without any manual operation, Raw material: SS 304, SS 316L, 2205, CS, nickel, titanium alloy, Cleaning differential pressure: 7psi (0.05Mpa), Self cleaning flow: <3% of filtration liquid flow, Control method: differential pressure control, PLC timing control. However, during the entire operation, the fluid will keep on flowing which allows operations to continue undisrupted. The unfiltered liquid enters the filter and the solid particles within the liquid are deposited on the interior surface of the filtration screen. You will find automatic self- cleaning air filter in air cleaning applications. Because of well-set position and optimum scraping angle, the rotational scraper drains off the impurities from the filter with the help of the gear motor.