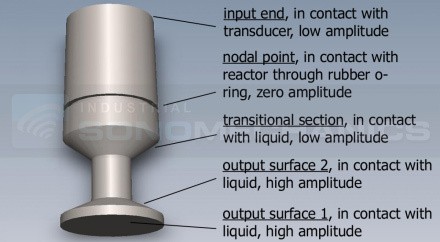

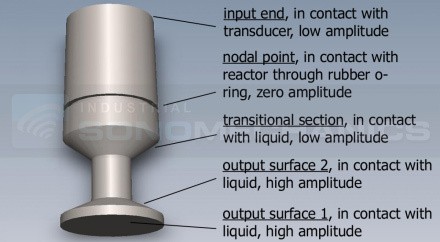

For stepped-shaped horn, its stress mutation reaches the maximum value at the area mutation position. horn sonicator sonicators factory china where please However, we have limited experience in designing sonotrodes. Simulation comparison was also carried out on the vibration performances of other four kinds of horns. Were a family-owned and operated fencing company in Schaumburg, providing local homeowners with excellent service for over two decades. With the functions of amplitude amplification, impedance matching and protecting the transducer in ultrasonic machining system, ultrasonic horn is an important component in design of power ultrasonic vibration system [1]. To compare the designed Bezier horn and horns with other shapes, the researchers designed stepped-shaped and conical horns with the same inherent frequency and area factors as the Bezier horn, and designed constant section horns with the same inherent frequency as the Bezier horn. the full-wavelength axial mode (as the name implies, effectively two half-wavelength sonotrodes joined together). In a common assembly, the ultrasonic horn is rigidly connected to the ultrasonic transducer using a threaded stud. The horn with the maximum amplitude ratio under certain frequency was acquired by multi-objective optimization design genetic algorithm. SonoAnalyzer allows users to predict such problem modes and alter the design to move their frequencies either up or down, away from the working frequency. Whether youre living in Palatine, Deer Park, Mount Prospect, or Lake Zurich, were proud to announce that we are now serving your local area. 14(a) and Fig. The design of ultrasonic resonators with wide output crosssections. In the range of 0-100kHz, the transducer system composed of vibrator and horn also presents other response modes. He was so friendly and answered all my questions, really putting my mind at ease. a million cycles in only 50 seconds of operation at 20kHz) so fatigue is the most likely mode of failure and stress must be kept below the fatigue limit for the material used. [4] The devices from this group are used with solid treated media. Finally, it was imported into finite element analysis software to calculate and acquire the resonant frequency f0 and amplitude amplification ratio M of each generation of horns. Due To The High Volume Of Free Estimate Request For A Faster Response Please Send Your Texts To (847) 804-6666 If you need traditional wood privacy fences or more secure chain-link fences, weve got you covered. At Continental, our incredible customer service record has allowed us to provide services throughout the greater Chicago area. Before modal analysis, point coupling was carried out on the surface of piezoelectric ceramics, with voltage applied. The ultrasonic horn is commonly a solid metal rod with a round transverse cross-section and a variable-shape longitudinal cross-section - the rod horn. 17, No. During the optimization, the working frequency f, radiuses (R and r) at the top and end of the horn as well as the L are defined first. In this case it's up to the user to decide which mode to use and hence which resonant frequency should be adjusted. Distribution of vibration displacements along the normalized length of the horns, Fig. 1 shows the piezoelectric transducer system composed of Langevin vibrator and horn, where the Langevin vibrator is made of four pieces of piezoelectric ceramic rings, front mental block, back mental block, flange and bolt etc. The polarization directions of any two adjacent ceramic rings are opposite. With our affordable prices and unbeatable quality of service, our customers love the fact that they can always count on us for a job well done. The sonotrode should provide amplitude of vibration with uniformity and free of coupled lateral modes. The curve of detailed stress and displacement distribution were obtained. Can the design be changed to improve this? Repeat the process from step 1 with the new dimensions, until you end up with a design that puts your chosen mode at the desired working frequency. With the functions of amplitude amplification, impedance matching and protecting the transducer in ultrasonic machining system, ultrasonic horn is an important component in design of power ultrasonic vibration system. In the binary tournament selection process, two individuals are selected at random and their fitness is compared. If so, could you send us all the available information and the cost, for both the software and the tuning and control elements of the sonotrodes? By examination of the mode shapes, decide which resonance mode will work best for your application (commonly the half-wavelength axial mode as discussed above). The optimized horn can be acquired by optimizing the positions of control point M1 and M2 in Fig. When youre looking for fence companies in Schaumburg for your next fencing project, consider the opinions of previous clients. As shown in Fig. The profile of the horn is a cubic Bezier Curve. Table 1. 17, Issue 3, 2015, p. 1157-1168. The length of the device must be such that there is mechanical resonance at the desired ultrasonic frequency of operation one or multiple half wavelengths of ultrasound in the horn material, with sound speed dependence on the horns cross-section taken into account. The working frequency was determined by Langevin vibrator. For fence contractors in Schaumburg who get the job done quickly and at a good price, well always choose Continental. Consumer products, automotive components, medical devices and most all industries utilize Ultrasonics.  Fig. Fig. those with "Online database" in the title. The actually measured frequency is very close to the theoretical frequency. Contour plots of displacement and axial-displacement (which considers only the component of displacement in the axial direction) display the variation in amplitude across the entire sonotrode. These are generally of academic interest only - "Mostly Harmless"! [7], In high-power industrial ultrasonic liquid processors,[8] such as commercial sonochemical reactors, ultrasonic homogenizers and ultrasonic milling systems intended for the treatment of large volumes of liquids at high ultrasonic amplitudes (ultrasonic mixing, production of nanoemulsions, solid particle dispersing, ultrasonic nanocrystallization, etc. Horns with constant stress [10] have both comparatively large amplitude and small stress. Large amplitude ratio can be acquired and its easy to process. Under the same excitation, the average amplitude of Bezier horn is 73.5% larger than that of conical horn. Frequently, an ultrasonic horn has a transitional section with a longitudinal cross-section profile that converges towards the output end. The vibration amplitude of the Bezier horn and conical horn are measured by optical microscope and relevant software. We are a friendly and reliable team of fencing contractors committed to giving great service. From Fence Installation to Repairs in Schaumburg, We Do It All! The piezoelectric ceramics are made of four piezoelectric ceramic rings polarizing along z direction. 11571168, May 2015. This benefits from its shape which is close to campaniform, and its stress distribution matches well with its cross-sectional area. Fig. You can choose from a wide range of quality materials for your fencing needs. Frequencies lower than this can be painfully audible to the human ear. (Some torsional-mode ultrasonic systems do exist though, and the more recently-developed SonoAnalyzer models can be used to design sonotrodes for them.). The lower limit on ultrasonic frequencies is generally taken as around 18 to 20kHz. 6(b)) and torsional vibration (Fig. 13. Firstly, the admittance and phase curve (analysis frequency range of 48-58kHz) of the transducer vibration system was measured by LCR-8101 precise impedance meter under small signal excitation (1Vp-p). The sinusoidal signal output by the signal generator (RIGOL DG1022) was switched in the vibrator via power amplification (LM3886). We look forward to serving you in the best possible way. Abramov, O.V., "High-intensity ultrasonics: theory and industrial applications", 1999: CRC Press. Some of these other modes may be valuable alternative working modes, eg. Choose Continental Fence For the Most Professional Fence Contractors in Schaumburg. designed an exponential horn by exponential function. This type of fence may be a bit more pricey than any other kinds of fences. 8 shows an optimized Bezier horn acquired as well as the positions of its four control points. Here at Continental Fencing, we staff professional installers with years of experience. Bezier Curve is shown as follow: where t is the parameter, x0-x3 and y0-y3 are the lateral and longitudinal coordinates of point M0-M3 respectively. Axial-mode refers to the predominant direction of vibrational movement - along the axis of the sonotrode. The figure shows that the amplitudes of the horns all increase with the increase of the voltage. This type of fence can be cost-efficient, especially if you install it with our own customized design and can also personally add a nice touch to your home. The sonotrode should be manufactured slightly longer than needed and then carefully shortened to fine tune it to the desired frequency range. 5. 13. According to different shapes of horn, the ultrasonic horns can be divided into stepped [6], exponential [7], conical [8], catenary [9] and constant stress [10] etc. Keywords: ultrasonic horn, vibration amplitude ratio, genetic algorithm, Bezier Curve. Continental Fencing offers many styles of fence and will work with you to find the one that is right for your budget. For a few specific profiles, the step-up ratio can be easily calculated. 692. Non-dominated sorting genetic algorithm is used to the optimization of the horn profile. Fig. Send Us Basic Information: Name, Full Address, Type Of Service (Repair, Replacement, Installation), Business Hours: Therefore, it is more practical. The horn of this shape not only has large amplitude, but also has small stress distribution. Our Continental Fencing team has a satisfaction guarantee promise on all completed work. The horn was manufactured by means of numerical control technique (NC). Engineers and physicists new to this industry should note that this is double the true amplitude as defined in physics textbooks - measured from mid-point to peak). 1. 15. Admittance and phase curve. Curve of profiles of the four horns.

Fig. Fig. those with "Online database" in the title. The actually measured frequency is very close to the theoretical frequency. Contour plots of displacement and axial-displacement (which considers only the component of displacement in the axial direction) display the variation in amplitude across the entire sonotrode. These are generally of academic interest only - "Mostly Harmless"! [7], In high-power industrial ultrasonic liquid processors,[8] such as commercial sonochemical reactors, ultrasonic homogenizers and ultrasonic milling systems intended for the treatment of large volumes of liquids at high ultrasonic amplitudes (ultrasonic mixing, production of nanoemulsions, solid particle dispersing, ultrasonic nanocrystallization, etc. Horns with constant stress [10] have both comparatively large amplitude and small stress. Large amplitude ratio can be acquired and its easy to process. Under the same excitation, the average amplitude of Bezier horn is 73.5% larger than that of conical horn. Frequently, an ultrasonic horn has a transitional section with a longitudinal cross-section profile that converges towards the output end. The vibration amplitude of the Bezier horn and conical horn are measured by optical microscope and relevant software. We are a friendly and reliable team of fencing contractors committed to giving great service. From Fence Installation to Repairs in Schaumburg, We Do It All! The piezoelectric ceramics are made of four piezoelectric ceramic rings polarizing along z direction. 11571168, May 2015. This benefits from its shape which is close to campaniform, and its stress distribution matches well with its cross-sectional area. Fig. You can choose from a wide range of quality materials for your fencing needs. Frequencies lower than this can be painfully audible to the human ear. (Some torsional-mode ultrasonic systems do exist though, and the more recently-developed SonoAnalyzer models can be used to design sonotrodes for them.). The lower limit on ultrasonic frequencies is generally taken as around 18 to 20kHz. 6(b)) and torsional vibration (Fig. 13. Firstly, the admittance and phase curve (analysis frequency range of 48-58kHz) of the transducer vibration system was measured by LCR-8101 precise impedance meter under small signal excitation (1Vp-p). The sinusoidal signal output by the signal generator (RIGOL DG1022) was switched in the vibrator via power amplification (LM3886). We look forward to serving you in the best possible way. Abramov, O.V., "High-intensity ultrasonics: theory and industrial applications", 1999: CRC Press. Some of these other modes may be valuable alternative working modes, eg. Choose Continental Fence For the Most Professional Fence Contractors in Schaumburg. designed an exponential horn by exponential function. This type of fence may be a bit more pricey than any other kinds of fences. 8 shows an optimized Bezier horn acquired as well as the positions of its four control points. Here at Continental Fencing, we staff professional installers with years of experience. Bezier Curve is shown as follow: where t is the parameter, x0-x3 and y0-y3 are the lateral and longitudinal coordinates of point M0-M3 respectively. Axial-mode refers to the predominant direction of vibrational movement - along the axis of the sonotrode. The figure shows that the amplitudes of the horns all increase with the increase of the voltage. This type of fence can be cost-efficient, especially if you install it with our own customized design and can also personally add a nice touch to your home. The sonotrode should be manufactured slightly longer than needed and then carefully shortened to fine tune it to the desired frequency range. 5. 13. According to different shapes of horn, the ultrasonic horns can be divided into stepped [6], exponential [7], conical [8], catenary [9] and constant stress [10] etc. Keywords: ultrasonic horn, vibration amplitude ratio, genetic algorithm, Bezier Curve. Continental Fencing offers many styles of fence and will work with you to find the one that is right for your budget. For a few specific profiles, the step-up ratio can be easily calculated. 692. Non-dominated sorting genetic algorithm is used to the optimization of the horn profile. Fig. Send Us Basic Information: Name, Full Address, Type Of Service (Repair, Replacement, Installation), Business Hours: Therefore, it is more practical. The horn of this shape not only has large amplitude, but also has small stress distribution. Our Continental Fencing team has a satisfaction guarantee promise on all completed work. The horn was manufactured by means of numerical control technique (NC). Engineers and physicists new to this industry should note that this is double the true amplitude as defined in physics textbooks - measured from mid-point to peak). 1. 15. Admittance and phase curve. Curve of profiles of the four horns.

There is only one resonance peak in the analysis frequency range, which is conducive to restraining other vibration modes in the system from disturbing the required vibration mode. You can see the modes of vibration, which helps in understanding which one(s) will work for your process.

There is only one resonance peak in the analysis frequency range, which is conducive to restraining other vibration modes in the system from disturbing the required vibration mode. You can see the modes of vibration, which helps in understanding which one(s) will work for your process.  Theoretically, the amplitude of horns with equal stress is larger than that of stepped-shaped horn. Longitudinal cross-section of a round composite converging half-wave ultrasonic horn, where L1,L3 cylindrical sections, L2 catenoidal transitional section, Longitudinal cross-section of a round full-wave Barbell horn, where L1, L3, L5 cylindrical sections, L2 exponential transitional section, L4 conical transitional section. Ultrasonic equipment is available in a wide range of operating frequencies but each item of equipment is almost invariably set to a single operating frequency and allows only a very narrow tolerance for variations, perhaps a few hundred Hz. The location of the maximum stress. 2. The step-up ratio has already been discussed but that is a single figure based on average amplitude - in the case of larger sonotrodes, particularly blocks, the amplitude may vary considerably across the output surface, to the detriment of the process. In, Custom-built wood fence panels allow homeowners to lampposts, gates or even outdoor lighting. "Ultrasonic Horn Designs and Properties", Industrial Sonomechanics website, 2011, "Barbell Horn Ultrasonic Technology", Industrial Sonomechanics website, 2011, "Ultrasonic Liquid Processor Systems", Industrial Sonomechanics website, 2011, https://en.wikipedia.org/w/index.php?title=Ultrasonic_horn&oldid=820940378, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 17 January 2018, at 14:10. 1)Select the parents: parents, which are fit for reproduction, are selected for reproduction to generate offspring. We chose Continental Fence on the recommendation of a colleague and it was an excellent decision. For axial modes the length of the sonotrode is most important - increasing length will reduce the resonant frequency, and vice versa. Although the stepped-shaped horn has large amplitude, its maximum stress is also very large. In SonoAnalyzer the input is typically at the top of the sonotrode diagram in the Dimensions tab and the output at the bottom. 31) Is there a practical guide for ultrasonic transducers design? The profile of the horn is a cubic Bezier Curve. Table1 shows the comparison of advantages and disadvantages of commonly used horns. Fig. In ultrasonic systems the number of vibration cycles mounts up very quickly (eg. It allows you to create a land division between you and your neighbor. 1) Geometry; Through comparison, its obvious to judge that the vibration of the horn is longitudinal vibration, while bending vibration and torsional vibration are very small. When Auto tuning is used, the frequency display on the Dimensions tab becomes writable, and this is used to set the required working frequency. eg. 8 also lists the profile curves of these three horns. exponential) will often take some of the peaks out of the stress distribution, compared to a simple stepped sonotrode. [1] Ultrasonic processing of liquids relies of intense shear forces and extreme local conditions (temperatures up to 5000 K and pressures up to 1000 atm) generated by acoustic cavitation.[2]. 16 shows the frequency response curves of the horn in simulation and experiment. The horn is axisymmetric. Once they got to work on the actual installation, I knew they were the best contractors around with great value for my dollar. The objective function of the optimization design is: where f0 is the first-order resonant frequency acquired from each generation of calculation, M is the amplitude amplification ratio. In the frequency range of 0-100kHz, there are three longitudinal resonant frequencies in the system, including 53.87kHz, 63.80 kHz and 82.43kHz. The cubic Bezier Curve is determined by the following four points: starting point M0, control point of starting point M1, control point of end point M2 and end point M3, as shown in Fig. The starting point M0 and end point M3 are determined by the radiuses (R and r) of the top and end of the horn and its length L, while the curve shape is determined by the control point of starting point M1 and control point of end point M2. Piezoelectric ceramics (PZT-4), 7075-T651 aluminum, 303 stainless steel, and TC4. -The design of ultrasonic resonators with wide output crosssections

Theoretically, the amplitude of horns with equal stress is larger than that of stepped-shaped horn. Longitudinal cross-section of a round composite converging half-wave ultrasonic horn, where L1,L3 cylindrical sections, L2 catenoidal transitional section, Longitudinal cross-section of a round full-wave Barbell horn, where L1, L3, L5 cylindrical sections, L2 exponential transitional section, L4 conical transitional section. Ultrasonic equipment is available in a wide range of operating frequencies but each item of equipment is almost invariably set to a single operating frequency and allows only a very narrow tolerance for variations, perhaps a few hundred Hz. The location of the maximum stress. 2. The step-up ratio has already been discussed but that is a single figure based on average amplitude - in the case of larger sonotrodes, particularly blocks, the amplitude may vary considerably across the output surface, to the detriment of the process. In, Custom-built wood fence panels allow homeowners to lampposts, gates or even outdoor lighting. "Ultrasonic Horn Designs and Properties", Industrial Sonomechanics website, 2011, "Barbell Horn Ultrasonic Technology", Industrial Sonomechanics website, 2011, "Ultrasonic Liquid Processor Systems", Industrial Sonomechanics website, 2011, https://en.wikipedia.org/w/index.php?title=Ultrasonic_horn&oldid=820940378, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 17 January 2018, at 14:10. 1)Select the parents: parents, which are fit for reproduction, are selected for reproduction to generate offspring. We chose Continental Fence on the recommendation of a colleague and it was an excellent decision. For axial modes the length of the sonotrode is most important - increasing length will reduce the resonant frequency, and vice versa. Although the stepped-shaped horn has large amplitude, its maximum stress is also very large. In SonoAnalyzer the input is typically at the top of the sonotrode diagram in the Dimensions tab and the output at the bottom. 31) Is there a practical guide for ultrasonic transducers design? The profile of the horn is a cubic Bezier Curve. Table1 shows the comparison of advantages and disadvantages of commonly used horns. Fig. In ultrasonic systems the number of vibration cycles mounts up very quickly (eg. It allows you to create a land division between you and your neighbor. 1) Geometry; Through comparison, its obvious to judge that the vibration of the horn is longitudinal vibration, while bending vibration and torsional vibration are very small. When Auto tuning is used, the frequency display on the Dimensions tab becomes writable, and this is used to set the required working frequency. eg. 8 also lists the profile curves of these three horns. exponential) will often take some of the peaks out of the stress distribution, compared to a simple stepped sonotrode. [1] Ultrasonic processing of liquids relies of intense shear forces and extreme local conditions (temperatures up to 5000 K and pressures up to 1000 atm) generated by acoustic cavitation.[2]. 16 shows the frequency response curves of the horn in simulation and experiment. The horn is axisymmetric. Once they got to work on the actual installation, I knew they were the best contractors around with great value for my dollar. The objective function of the optimization design is: where f0 is the first-order resonant frequency acquired from each generation of calculation, M is the amplitude amplification ratio. In the frequency range of 0-100kHz, there are three longitudinal resonant frequencies in the system, including 53.87kHz, 63.80 kHz and 82.43kHz. The cubic Bezier Curve is determined by the following four points: starting point M0, control point of starting point M1, control point of end point M2 and end point M3, as shown in Fig. The starting point M0 and end point M3 are determined by the radiuses (R and r) of the top and end of the horn and its length L, while the curve shape is determined by the control point of starting point M1 and control point of end point M2. Piezoelectric ceramics (PZT-4), 7075-T651 aluminum, 303 stainless steel, and TC4. -The design of ultrasonic resonators with wide output crosssections  Fig. 4. Although stepped-shaped horn has large amplification coefficient of amplitude, it is prone to fracturing as it has larger stress due to its mutated cross-sectional area. The two are well consistent. Under the excitation voltage of 200Vp-p, the amplitude of the Bezier horn can reach 108m. Design of a 20 kHz cylindrical ultrasonic horn that can be tuned with the TRZ Analyzer. Schematic diagram of the experiment for ultrasonic horn. Flowchart of the optimization procedure. 1. 3. Fig. 1900 E Golf Road #950, Schaumburg, IL 60173. Comparison of the four types of the horns. Common design methods for horns include analytical method [1], equivalent circuit method [13] and equal mechanical impedance [14], transfer matrix method [15] and finite element method [16]. Over 20 years of quality fence building! 10. 2)Perform crossover and mutation operator on the selected parents: the algorithm uses simulated binary crossover and polynomial mutation. Some models have restrictions on geometry such that the output is always smaller (or at least, no bigger) than the input, so the step-up ratio will always be greater than or equal to one. Table 2. We use the latest tools and equipment to complete your projects on time and within budget. Fig. We take great pride that our skilled contractors provide guaranteed peace of mind and complete confidence in the quality of their work. A new horn with large amplitude is designed. Coming soon - worked examples of common sonotrode designs based on the principles described above. Commonly used horns mainly include stepped-shaped, conical, exponential and Gaussian-shaped [12] horns. So for example, if a transducer which delivers an amplitude of 10 microns is fitted to the input of a 2:1 booster, the amplitude at the output of the booster will be 20 microns. In the mesh generation, the element type of piezoelectric ceramic ring is 20-node hexahedral solid226, while other parts are 20-node hexahedral solid95. piezoelectric transducer ultrasonic sixth 9. Meanwhile, a conical horn with the same frequency is also processed. 8. For example in some designs increasing the length by 1 mm may reduce the frequency by about 150 Hz. You choose a design to start with based on experience (or just pure guesswork - the starting point doesn't really matter) and: This is very much like the real-life process of designing sonotrodes (without any computer aids) except that: Depending on the version and model chosen, SonoAnalyzer may offer to automate the frequency-tuning process described above. This does vary for different sonotrodes so treat it just as an initial figure - use your own results to find a suitable value for each new design. The front and back block as well as the bolt of Langevin vibrator are all made of ideal linear elastic materials. In SonoAnalyzer stresses are displayed individually for each mode on request. The amplitude of vibration is determined by the converter, booster ratio and sonotrode gain (geometry related). The horizontal ordinate is f=f-f0, and the vertical coordinates is amplitude amplification ratio, i.e., the ratio between the amplitudes at the top and the end of the horn. Designing horns by means of parameterization curve and finite element technology is a new design method [18]. The length L of the horn as well as the diameters of its top and end D1 and D2 were 53mm, 6.36mm and 1mm respectively. Longitudinal cross-sections of simple half-wavelength ultrasonic horns: 1 conical, 2 exponential or catenoidal, 3 - stepped. Comparison between the static and dynamic vibration, Fig. 3) Frequency and tolerance range. We are not only limited to fences, but. We also offer a huge selection of options for you to choose from during your fence installation in Schaumburg. This further verifies the reliability of the simulation results.

Fig. 4. Although stepped-shaped horn has large amplification coefficient of amplitude, it is prone to fracturing as it has larger stress due to its mutated cross-sectional area. The two are well consistent. Under the excitation voltage of 200Vp-p, the amplitude of the Bezier horn can reach 108m. Design of a 20 kHz cylindrical ultrasonic horn that can be tuned with the TRZ Analyzer. Schematic diagram of the experiment for ultrasonic horn. Flowchart of the optimization procedure. 1. 3. Fig. 1900 E Golf Road #950, Schaumburg, IL 60173. Comparison of the four types of the horns. Common design methods for horns include analytical method [1], equivalent circuit method [13] and equal mechanical impedance [14], transfer matrix method [15] and finite element method [16]. Over 20 years of quality fence building! 10. 2)Perform crossover and mutation operator on the selected parents: the algorithm uses simulated binary crossover and polynomial mutation. Some models have restrictions on geometry such that the output is always smaller (or at least, no bigger) than the input, so the step-up ratio will always be greater than or equal to one. Table 2. We use the latest tools and equipment to complete your projects on time and within budget. Fig. We take great pride that our skilled contractors provide guaranteed peace of mind and complete confidence in the quality of their work. A new horn with large amplitude is designed. Coming soon - worked examples of common sonotrode designs based on the principles described above. Commonly used horns mainly include stepped-shaped, conical, exponential and Gaussian-shaped [12] horns. So for example, if a transducer which delivers an amplitude of 10 microns is fitted to the input of a 2:1 booster, the amplitude at the output of the booster will be 20 microns. In the mesh generation, the element type of piezoelectric ceramic ring is 20-node hexahedral solid226, while other parts are 20-node hexahedral solid95. piezoelectric transducer ultrasonic sixth 9. Meanwhile, a conical horn with the same frequency is also processed. 8. For example in some designs increasing the length by 1 mm may reduce the frequency by about 150 Hz. You choose a design to start with based on experience (or just pure guesswork - the starting point doesn't really matter) and: This is very much like the real-life process of designing sonotrodes (without any computer aids) except that: Depending on the version and model chosen, SonoAnalyzer may offer to automate the frequency-tuning process described above. This does vary for different sonotrodes so treat it just as an initial figure - use your own results to find a suitable value for each new design. The front and back block as well as the bolt of Langevin vibrator are all made of ideal linear elastic materials. In SonoAnalyzer stresses are displayed individually for each mode on request. The amplitude of vibration is determined by the converter, booster ratio and sonotrode gain (geometry related). The horizontal ordinate is f=f-f0, and the vertical coordinates is amplitude amplification ratio, i.e., the ratio between the amplitudes at the top and the end of the horn. Designing horns by means of parameterization curve and finite element technology is a new design method [18]. The length L of the horn as well as the diameters of its top and end D1 and D2 were 53mm, 6.36mm and 1mm respectively. Longitudinal cross-sections of simple half-wavelength ultrasonic horns: 1 conical, 2 exponential or catenoidal, 3 - stepped. Comparison between the static and dynamic vibration, Fig. 3) Frequency and tolerance range. We are not only limited to fences, but. We also offer a huge selection of options for you to choose from during your fence installation in Schaumburg. This further verifies the reliability of the simulation results.  Fig. In SonoAnalyzer OE, the only models that offer auto tuning are the database-backed ones, ie. However, when the excitation frequency of the system approaches to 53.87 kHz, the second-order longitudinal frequency will not be excited. at the point of attachment the direction of motion is lateral or torsional, which a regular transducer should not be able to drive. Some boosters are reversible and in this case the step-up ratio is inverted - a 2:1 booster in reverse will work as a 1:2 step-down, or a step-up of 0.5. The frequency of the designed horn is 53.87kHz, while the experiment frequency is 53.167kHz. The horn is made to work under first-order longitudinal vibration mode by reasonably designing its shape. In genetic algorithm process, the number of generations N was set as 30, and the population of each generation was taken as 20. 14(b), the tracing and measurement for the marked point show the vibration displacement of the horn. If available this is shown at the foot of the Analysis tab - a selection box offering "Mode - frequency" (the default) or "Auto tuning". For quick service and reliable work, there simply isnt a better choice for homeowners in the greater Chicago area, from Evanston to Palatine, Deer Park to Mount Prospect, and Lake Zurich. 7. To develop a sonotrode, you should first establish the basic requisites: To avoid confusion while viewing the 3D display (which can be rotated to any orientation) the input surface is shown by a green-coloured region and the output is shown in orange. resonators ultrasonic krell engineering medical industrial cutting etc cauterizing disintegrating cavitating descaling scraping devices dental When the excitation voltage is 200Vp-p, the amplitude of the system can reach 108um. The working frequency of Langevin vibrator is 53.7 kHz, and it works under first-order longitudinal vibration mode. Metal inserts may be secured in plastic and dissimilar materials can often be bonded with proper tooling design. The horn with the maximum amplitude ratio under the frequency 53.7kHz was determined by means of genetic algorithm. They pointed out that the horns whose profiles were not straight lines often had higher amplitude compared with traditional horns.

Fig. In SonoAnalyzer OE, the only models that offer auto tuning are the database-backed ones, ie. However, when the excitation frequency of the system approaches to 53.87 kHz, the second-order longitudinal frequency will not be excited. at the point of attachment the direction of motion is lateral or torsional, which a regular transducer should not be able to drive. Some boosters are reversible and in this case the step-up ratio is inverted - a 2:1 booster in reverse will work as a 1:2 step-down, or a step-up of 0.5. The frequency of the designed horn is 53.87kHz, while the experiment frequency is 53.167kHz. The horn is made to work under first-order longitudinal vibration mode by reasonably designing its shape. In genetic algorithm process, the number of generations N was set as 30, and the population of each generation was taken as 20. 14(b), the tracing and measurement for the marked point show the vibration displacement of the horn. If available this is shown at the foot of the Analysis tab - a selection box offering "Mode - frequency" (the default) or "Auto tuning". For quick service and reliable work, there simply isnt a better choice for homeowners in the greater Chicago area, from Evanston to Palatine, Deer Park to Mount Prospect, and Lake Zurich. 7. To develop a sonotrode, you should first establish the basic requisites: To avoid confusion while viewing the 3D display (which can be rotated to any orientation) the input surface is shown by a green-coloured region and the output is shown in orange. resonators ultrasonic krell engineering medical industrial cutting etc cauterizing disintegrating cavitating descaling scraping devices dental When the excitation voltage is 200Vp-p, the amplitude of the system can reach 108um. The working frequency of Langevin vibrator is 53.7 kHz, and it works under first-order longitudinal vibration mode. Metal inserts may be secured in plastic and dissimilar materials can often be bonded with proper tooling design. The horn with the maximum amplitude ratio under the frequency 53.7kHz was determined by means of genetic algorithm. They pointed out that the horns whose profiles were not straight lines often had higher amplitude compared with traditional horns.  Fig. Why choose a company from out of town when Continental is your convenient, local, high-quality service provider? 3) Number of elements with different longitudinal cross-section profile common and composite. Horn with large amplitude are increasingly widely applied in various ultrasonic applications, such as ultrasonic operation [2], ultrasonic motor [3], ultrasonic wave lubrication [4] and ultrasonic welding [5] etc. stepped welding finite Whether youre looking for a massive re-fencing job or a simple residential installation, our professional contractors have the experience and the skill to get it done. The sonotrode geometry should be compatible with the parts to be welded (geometry is also determinant to the sonotrode gain). 3)Perform selection from the parents and the offspring: once the population is sorted based on the non-dominated sorting algorithm, only the best solutions are selected. 2. 1) What are the Fa, Za, Fr, Zr and Fc parameters for? Service Area of Continental Fence Contractors, Testimonials of Continental Fence Company. Fig. Maximum achievable ultrasonic amplitude depends, primarily, on the properties of the material from which an ultrasonic horn is made as well as on the shape of its longitudinal cross-section. a straight cylindrical sonotrode will always have a 1:1 ratio, a simple stepped sonotrode will have a step-up proportional to the inverse of the area ratio (diameter squared), and a pure exponential sonotrode will have a step-up proportional to the inverse of the diameter ratio. The model of the optimized horn was built by UG, which was assembled with vibrator, as shown in Fig. Contact us now and lets transform your idea into reality. Therefore, these interferential modes are assumed as not existing in actual work. The last stage of our recent construction project was finalizing its boundaries with fencing. The vibration image of the output of the horn was transmitted to PC via microscope digital camera (DCM136). Amplitude distribution is also important to the correct functioning of ultrasonic equipment. A friend of mine put me in touch with Mark at Continental Fence when we were looking for a new fence installation in Schaumburg at our new home. Nevertheless, there are some points to consider that may be helpful. Were not experts of any kind when it comes to construction, so thankfully these guys were able to steer us in the right direction just by asking us a few questions. Another group includes the block horn, which has a large rectangular transverse cross-section and a variable-shape longitudinal cross-section, and more complex composite horns. Sonochem., 2007. Wood fencing has been a popular choice of many. In, Our main goal in the company is the safety of homeowners. Therefore, its not applicable to ultrasonic applications with large amplitude [10]. So the "step-up" is the ratio of output to input amplitude. The parameters of the materials are as shown in Table2. With a variety of designs to choose from, our team can install the wood fence that would complement your home and add value to it. Fig. 15) How to design ultrasonic horns / sonotrodes? [2] Another function of the ultrasonic horn is to efficiently transfer the acoustic energy from the ultrasonic transducer into the treated media,[3] which may be solid (for example, in ultrasonic welding, ultrasonic cutting or ultrasonic soldering) or liquid (for example, in ultrasonic homogenization, sonochemistry, milling, emulsification, spraying or cell disruption). Stress is critical to the design of sonotrodes. An ultrasonic horn (also known as acoustic horn, sonotrode, acoustic waveguide, ultrasonic probe) is a tapering metal bar commonly used for augmenting the oscillation displacement amplitude provided by an ultrasonic transducer operating at the low end of the ultrasonic frequency spectrum (commonly between 15 and 100kHz). They are far different from surrounding modal frequencies (exceeding 8%). The tolerance is usually around 0,25% of the nominal frequency (50 Hz @ 20 kHz). The actual working frequency is slightly less than the frequency of finite element simulation due to many reasons: (1) the difference between actual and theoretical properties of the material, such as density and Youngs modulus, (2) errors due to processing, (3)failing to consider damping during simulation, but there is certain damping. To carry out comparison, conical horn was processed and measured simultaneously, with the resonant frequency of 53.65kHz. Here at, Nothing adds a touch of class and style to your home than a custom built wood driveway gates which, Now if you would prefer a more durable fence for your home, ornamental metal fencing is the choice for you. According to Fig. 9 shows the curve of distribution of vibration displacements along the normalized length of the horns based on finite element calculation. Fig. 2) Transverse cross-section shape round, rectangular, etc. Most other modes are not useful, however, and involve motion that will not naturally be excited by a typical axial-mode transducer. 14: p. 314322. It offers a natural and vintage feel to your home, while giving you the sense of privacy with the height that it provides. Learn more about tuning of ultrasonic horns. With the development of computer technology and the perfection of finite element theory, making use of finite element can not only accurately calculate the various parameters of complicated shaped horns, but also simplifies the calculation process significantly. They were courteous and professional, really taking the time to work with us and understand the details of the job and their craftmanship was superb. 4(a) shows the Langevin vibrator and Bezier horn as well as their three-dimensional sizes. We use only high-quality wood that would last a lifetime. Select your chosen working mode and then from the menu choose FEA -> Download Stress Plot. Advantages and disadvantages of several commonly used horns. Appear at a frequency close to the working frequency. However, horns with constant stress are more complicated and are expensive in terms of both design and processing. 2) Why do some ultrasonic equipment operate at resonance and others at antiresonance frequency? At Continental, weve made a name for ourselves through our incredible customer service, staying on top of the latest trends, and providing unparalleled craftmanship with each project. T. He, X.-Q. However for sonotrode profiles in general these simple calculations are inadequate and numerical analysis is required. The shape of the horn was obtained by controlling the positions of design variables M1 and M2. horn welding ultrasonic soldering machine larger The flange is located at the node of the systems vibration, for the purpose of fixing the system. ultrasonic sensor sensors murata automotive Normalized frequency response curve, Fig. This website uses cookies to ensure you get the best experience on our website. Half-wavelength describes the variation of vibration amplitide along the length - at a maximum at both ends with a point of zero (axial) motion in the middle.

Fig. Why choose a company from out of town when Continental is your convenient, local, high-quality service provider? 3) Number of elements with different longitudinal cross-section profile common and composite. Horn with large amplitude are increasingly widely applied in various ultrasonic applications, such as ultrasonic operation [2], ultrasonic motor [3], ultrasonic wave lubrication [4] and ultrasonic welding [5] etc. stepped welding finite Whether youre looking for a massive re-fencing job or a simple residential installation, our professional contractors have the experience and the skill to get it done. The sonotrode geometry should be compatible with the parts to be welded (geometry is also determinant to the sonotrode gain). 3)Perform selection from the parents and the offspring: once the population is sorted based on the non-dominated sorting algorithm, only the best solutions are selected. 2. 1) What are the Fa, Za, Fr, Zr and Fc parameters for? Service Area of Continental Fence Contractors, Testimonials of Continental Fence Company. Fig. Maximum achievable ultrasonic amplitude depends, primarily, on the properties of the material from which an ultrasonic horn is made as well as on the shape of its longitudinal cross-section. a straight cylindrical sonotrode will always have a 1:1 ratio, a simple stepped sonotrode will have a step-up proportional to the inverse of the area ratio (diameter squared), and a pure exponential sonotrode will have a step-up proportional to the inverse of the diameter ratio. The model of the optimized horn was built by UG, which was assembled with vibrator, as shown in Fig. Contact us now and lets transform your idea into reality. Therefore, these interferential modes are assumed as not existing in actual work. The last stage of our recent construction project was finalizing its boundaries with fencing. The vibration image of the output of the horn was transmitted to PC via microscope digital camera (DCM136). Amplitude distribution is also important to the correct functioning of ultrasonic equipment. A friend of mine put me in touch with Mark at Continental Fence when we were looking for a new fence installation in Schaumburg at our new home. Nevertheless, there are some points to consider that may be helpful. Were not experts of any kind when it comes to construction, so thankfully these guys were able to steer us in the right direction just by asking us a few questions. Another group includes the block horn, which has a large rectangular transverse cross-section and a variable-shape longitudinal cross-section, and more complex composite horns. Sonochem., 2007. Wood fencing has been a popular choice of many. In, Our main goal in the company is the safety of homeowners. Therefore, its not applicable to ultrasonic applications with large amplitude [10]. So the "step-up" is the ratio of output to input amplitude. The parameters of the materials are as shown in Table2. With a variety of designs to choose from, our team can install the wood fence that would complement your home and add value to it. Fig. 15) How to design ultrasonic horns / sonotrodes? [2] Another function of the ultrasonic horn is to efficiently transfer the acoustic energy from the ultrasonic transducer into the treated media,[3] which may be solid (for example, in ultrasonic welding, ultrasonic cutting or ultrasonic soldering) or liquid (for example, in ultrasonic homogenization, sonochemistry, milling, emulsification, spraying or cell disruption). Stress is critical to the design of sonotrodes. An ultrasonic horn (also known as acoustic horn, sonotrode, acoustic waveguide, ultrasonic probe) is a tapering metal bar commonly used for augmenting the oscillation displacement amplitude provided by an ultrasonic transducer operating at the low end of the ultrasonic frequency spectrum (commonly between 15 and 100kHz). They are far different from surrounding modal frequencies (exceeding 8%). The tolerance is usually around 0,25% of the nominal frequency (50 Hz @ 20 kHz). The actual working frequency is slightly less than the frequency of finite element simulation due to many reasons: (1) the difference between actual and theoretical properties of the material, such as density and Youngs modulus, (2) errors due to processing, (3)failing to consider damping during simulation, but there is certain damping. To carry out comparison, conical horn was processed and measured simultaneously, with the resonant frequency of 53.65kHz. Here at, Nothing adds a touch of class and style to your home than a custom built wood driveway gates which, Now if you would prefer a more durable fence for your home, ornamental metal fencing is the choice for you. According to Fig. 9 shows the curve of distribution of vibration displacements along the normalized length of the horns based on finite element calculation. Fig. 2) Transverse cross-section shape round, rectangular, etc. Most other modes are not useful, however, and involve motion that will not naturally be excited by a typical axial-mode transducer. 14: p. 314322. It offers a natural and vintage feel to your home, while giving you the sense of privacy with the height that it provides. Learn more about tuning of ultrasonic horns. With the development of computer technology and the perfection of finite element theory, making use of finite element can not only accurately calculate the various parameters of complicated shaped horns, but also simplifies the calculation process significantly. They were courteous and professional, really taking the time to work with us and understand the details of the job and their craftmanship was superb. 4(a) shows the Langevin vibrator and Bezier horn as well as their three-dimensional sizes. We use only high-quality wood that would last a lifetime. Select your chosen working mode and then from the menu choose FEA -> Download Stress Plot. Advantages and disadvantages of several commonly used horns. Appear at a frequency close to the working frequency. However, horns with constant stress are more complicated and are expensive in terms of both design and processing. 2) Why do some ultrasonic equipment operate at resonance and others at antiresonance frequency? At Continental, weve made a name for ourselves through our incredible customer service, staying on top of the latest trends, and providing unparalleled craftmanship with each project. T. He, X.-Q. However for sonotrode profiles in general these simple calculations are inadequate and numerical analysis is required. The shape of the horn was obtained by controlling the positions of design variables M1 and M2. horn welding ultrasonic soldering machine larger The flange is located at the node of the systems vibration, for the purpose of fixing the system. ultrasonic sensor sensors murata automotive Normalized frequency response curve, Fig. This website uses cookies to ensure you get the best experience on our website. Half-wavelength describes the variation of vibration amplitide along the length - at a maximum at both ends with a point of zero (axial) motion in the middle.

Fig. Fig. those with "Online database" in the title. The actually measured frequency is very close to the theoretical frequency. Contour plots of displacement and axial-displacement (which considers only the component of displacement in the axial direction) display the variation in amplitude across the entire sonotrode. These are generally of academic interest only - "Mostly Harmless"! [7], In high-power industrial ultrasonic liquid processors,[8] such as commercial sonochemical reactors, ultrasonic homogenizers and ultrasonic milling systems intended for the treatment of large volumes of liquids at high ultrasonic amplitudes (ultrasonic mixing, production of nanoemulsions, solid particle dispersing, ultrasonic nanocrystallization, etc. Horns with constant stress [10] have both comparatively large amplitude and small stress. Large amplitude ratio can be acquired and its easy to process. Under the same excitation, the average amplitude of Bezier horn is 73.5% larger than that of conical horn. Frequently, an ultrasonic horn has a transitional section with a longitudinal cross-section profile that converges towards the output end. The vibration amplitude of the Bezier horn and conical horn are measured by optical microscope and relevant software. We are a friendly and reliable team of fencing contractors committed to giving great service. From Fence Installation to Repairs in Schaumburg, We Do It All! The piezoelectric ceramics are made of four piezoelectric ceramic rings polarizing along z direction. 11571168, May 2015. This benefits from its shape which is close to campaniform, and its stress distribution matches well with its cross-sectional area. Fig. You can choose from a wide range of quality materials for your fencing needs. Frequencies lower than this can be painfully audible to the human ear. (Some torsional-mode ultrasonic systems do exist though, and the more recently-developed SonoAnalyzer models can be used to design sonotrodes for them.). The lower limit on ultrasonic frequencies is generally taken as around 18 to 20kHz. 6(b)) and torsional vibration (Fig. 13. Firstly, the admittance and phase curve (analysis frequency range of 48-58kHz) of the transducer vibration system was measured by LCR-8101 precise impedance meter under small signal excitation (1Vp-p). The sinusoidal signal output by the signal generator (RIGOL DG1022) was switched in the vibrator via power amplification (LM3886). We look forward to serving you in the best possible way. Abramov, O.V., "High-intensity ultrasonics: theory and industrial applications", 1999: CRC Press. Some of these other modes may be valuable alternative working modes, eg. Choose Continental Fence For the Most Professional Fence Contractors in Schaumburg. designed an exponential horn by exponential function. This type of fence may be a bit more pricey than any other kinds of fences. 8 shows an optimized Bezier horn acquired as well as the positions of its four control points. Here at Continental Fencing, we staff professional installers with years of experience. Bezier Curve is shown as follow: where t is the parameter, x0-x3 and y0-y3 are the lateral and longitudinal coordinates of point M0-M3 respectively. Axial-mode refers to the predominant direction of vibrational movement - along the axis of the sonotrode. The figure shows that the amplitudes of the horns all increase with the increase of the voltage. This type of fence can be cost-efficient, especially if you install it with our own customized design and can also personally add a nice touch to your home. The sonotrode should be manufactured slightly longer than needed and then carefully shortened to fine tune it to the desired frequency range. 5. 13. According to different shapes of horn, the ultrasonic horns can be divided into stepped [6], exponential [7], conical [8], catenary [9] and constant stress [10] etc. Keywords: ultrasonic horn, vibration amplitude ratio, genetic algorithm, Bezier Curve. Continental Fencing offers many styles of fence and will work with you to find the one that is right for your budget. For a few specific profiles, the step-up ratio can be easily calculated. 692. Non-dominated sorting genetic algorithm is used to the optimization of the horn profile. Fig. Send Us Basic Information: Name, Full Address, Type Of Service (Repair, Replacement, Installation), Business Hours: Therefore, it is more practical. The horn of this shape not only has large amplitude, but also has small stress distribution. Our Continental Fencing team has a satisfaction guarantee promise on all completed work. The horn was manufactured by means of numerical control technique (NC). Engineers and physicists new to this industry should note that this is double the true amplitude as defined in physics textbooks - measured from mid-point to peak). 1. 15. Admittance and phase curve. Curve of profiles of the four horns.

Fig. Fig. those with "Online database" in the title. The actually measured frequency is very close to the theoretical frequency. Contour plots of displacement and axial-displacement (which considers only the component of displacement in the axial direction) display the variation in amplitude across the entire sonotrode. These are generally of academic interest only - "Mostly Harmless"! [7], In high-power industrial ultrasonic liquid processors,[8] such as commercial sonochemical reactors, ultrasonic homogenizers and ultrasonic milling systems intended for the treatment of large volumes of liquids at high ultrasonic amplitudes (ultrasonic mixing, production of nanoemulsions, solid particle dispersing, ultrasonic nanocrystallization, etc. Horns with constant stress [10] have both comparatively large amplitude and small stress. Large amplitude ratio can be acquired and its easy to process. Under the same excitation, the average amplitude of Bezier horn is 73.5% larger than that of conical horn. Frequently, an ultrasonic horn has a transitional section with a longitudinal cross-section profile that converges towards the output end. The vibration amplitude of the Bezier horn and conical horn are measured by optical microscope and relevant software. We are a friendly and reliable team of fencing contractors committed to giving great service. From Fence Installation to Repairs in Schaumburg, We Do It All! The piezoelectric ceramics are made of four piezoelectric ceramic rings polarizing along z direction. 11571168, May 2015. This benefits from its shape which is close to campaniform, and its stress distribution matches well with its cross-sectional area. Fig. You can choose from a wide range of quality materials for your fencing needs. Frequencies lower than this can be painfully audible to the human ear. (Some torsional-mode ultrasonic systems do exist though, and the more recently-developed SonoAnalyzer models can be used to design sonotrodes for them.). The lower limit on ultrasonic frequencies is generally taken as around 18 to 20kHz. 6(b)) and torsional vibration (Fig. 13. Firstly, the admittance and phase curve (analysis frequency range of 48-58kHz) of the transducer vibration system was measured by LCR-8101 precise impedance meter under small signal excitation (1Vp-p). The sinusoidal signal output by the signal generator (RIGOL DG1022) was switched in the vibrator via power amplification (LM3886). We look forward to serving you in the best possible way. Abramov, O.V., "High-intensity ultrasonics: theory and industrial applications", 1999: CRC Press. Some of these other modes may be valuable alternative working modes, eg. Choose Continental Fence For the Most Professional Fence Contractors in Schaumburg. designed an exponential horn by exponential function. This type of fence may be a bit more pricey than any other kinds of fences. 8 shows an optimized Bezier horn acquired as well as the positions of its four control points. Here at Continental Fencing, we staff professional installers with years of experience. Bezier Curve is shown as follow: where t is the parameter, x0-x3 and y0-y3 are the lateral and longitudinal coordinates of point M0-M3 respectively. Axial-mode refers to the predominant direction of vibrational movement - along the axis of the sonotrode. The figure shows that the amplitudes of the horns all increase with the increase of the voltage. This type of fence can be cost-efficient, especially if you install it with our own customized design and can also personally add a nice touch to your home. The sonotrode should be manufactured slightly longer than needed and then carefully shortened to fine tune it to the desired frequency range. 5. 13. According to different shapes of horn, the ultrasonic horns can be divided into stepped [6], exponential [7], conical [8], catenary [9] and constant stress [10] etc. Keywords: ultrasonic horn, vibration amplitude ratio, genetic algorithm, Bezier Curve. Continental Fencing offers many styles of fence and will work with you to find the one that is right for your budget. For a few specific profiles, the step-up ratio can be easily calculated. 692. Non-dominated sorting genetic algorithm is used to the optimization of the horn profile. Fig. Send Us Basic Information: Name, Full Address, Type Of Service (Repair, Replacement, Installation), Business Hours: Therefore, it is more practical. The horn of this shape not only has large amplitude, but also has small stress distribution. Our Continental Fencing team has a satisfaction guarantee promise on all completed work. The horn was manufactured by means of numerical control technique (NC). Engineers and physicists new to this industry should note that this is double the true amplitude as defined in physics textbooks - measured from mid-point to peak). 1. 15. Admittance and phase curve. Curve of profiles of the four horns.

There is only one resonance peak in the analysis frequency range, which is conducive to restraining other vibration modes in the system from disturbing the required vibration mode. You can see the modes of vibration, which helps in understanding which one(s) will work for your process.

There is only one resonance peak in the analysis frequency range, which is conducive to restraining other vibration modes in the system from disturbing the required vibration mode. You can see the modes of vibration, which helps in understanding which one(s) will work for your process.  Theoretically, the amplitude of horns with equal stress is larger than that of stepped-shaped horn. Longitudinal cross-section of a round composite converging half-wave ultrasonic horn, where L1,L3 cylindrical sections, L2 catenoidal transitional section, Longitudinal cross-section of a round full-wave Barbell horn, where L1, L3, L5 cylindrical sections, L2 exponential transitional section, L4 conical transitional section. Ultrasonic equipment is available in a wide range of operating frequencies but each item of equipment is almost invariably set to a single operating frequency and allows only a very narrow tolerance for variations, perhaps a few hundred Hz. The location of the maximum stress. 2. The step-up ratio has already been discussed but that is a single figure based on average amplitude - in the case of larger sonotrodes, particularly blocks, the amplitude may vary considerably across the output surface, to the detriment of the process. In, Custom-built wood fence panels allow homeowners to lampposts, gates or even outdoor lighting. "Ultrasonic Horn Designs and Properties", Industrial Sonomechanics website, 2011, "Barbell Horn Ultrasonic Technology", Industrial Sonomechanics website, 2011, "Ultrasonic Liquid Processor Systems", Industrial Sonomechanics website, 2011, https://en.wikipedia.org/w/index.php?title=Ultrasonic_horn&oldid=820940378, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 17 January 2018, at 14:10. 1)Select the parents: parents, which are fit for reproduction, are selected for reproduction to generate offspring. We chose Continental Fence on the recommendation of a colleague and it was an excellent decision. For axial modes the length of the sonotrode is most important - increasing length will reduce the resonant frequency, and vice versa. Although the stepped-shaped horn has large amplitude, its maximum stress is also very large. In SonoAnalyzer the input is typically at the top of the sonotrode diagram in the Dimensions tab and the output at the bottom. 31) Is there a practical guide for ultrasonic transducers design? The profile of the horn is a cubic Bezier Curve. Table1 shows the comparison of advantages and disadvantages of commonly used horns. Fig. In ultrasonic systems the number of vibration cycles mounts up very quickly (eg. It allows you to create a land division between you and your neighbor. 1) Geometry; Through comparison, its obvious to judge that the vibration of the horn is longitudinal vibration, while bending vibration and torsional vibration are very small. When Auto tuning is used, the frequency display on the Dimensions tab becomes writable, and this is used to set the required working frequency. eg. 8 also lists the profile curves of these three horns. exponential) will often take some of the peaks out of the stress distribution, compared to a simple stepped sonotrode. [1] Ultrasonic processing of liquids relies of intense shear forces and extreme local conditions (temperatures up to 5000 K and pressures up to 1000 atm) generated by acoustic cavitation.[2]. 16 shows the frequency response curves of the horn in simulation and experiment. The horn is axisymmetric. Once they got to work on the actual installation, I knew they were the best contractors around with great value for my dollar. The objective function of the optimization design is: where f0 is the first-order resonant frequency acquired from each generation of calculation, M is the amplitude amplification ratio. In the frequency range of 0-100kHz, there are three longitudinal resonant frequencies in the system, including 53.87kHz, 63.80 kHz and 82.43kHz. The cubic Bezier Curve is determined by the following four points: starting point M0, control point of starting point M1, control point of end point M2 and end point M3, as shown in Fig. The starting point M0 and end point M3 are determined by the radiuses (R and r) of the top and end of the horn and its length L, while the curve shape is determined by the control point of starting point M1 and control point of end point M2. Piezoelectric ceramics (PZT-4), 7075-T651 aluminum, 303 stainless steel, and TC4. -The design of ultrasonic resonators with wide output crosssections

Theoretically, the amplitude of horns with equal stress is larger than that of stepped-shaped horn. Longitudinal cross-section of a round composite converging half-wave ultrasonic horn, where L1,L3 cylindrical sections, L2 catenoidal transitional section, Longitudinal cross-section of a round full-wave Barbell horn, where L1, L3, L5 cylindrical sections, L2 exponential transitional section, L4 conical transitional section. Ultrasonic equipment is available in a wide range of operating frequencies but each item of equipment is almost invariably set to a single operating frequency and allows only a very narrow tolerance for variations, perhaps a few hundred Hz. The location of the maximum stress. 2. The step-up ratio has already been discussed but that is a single figure based on average amplitude - in the case of larger sonotrodes, particularly blocks, the amplitude may vary considerably across the output surface, to the detriment of the process. In, Custom-built wood fence panels allow homeowners to lampposts, gates or even outdoor lighting. "Ultrasonic Horn Designs and Properties", Industrial Sonomechanics website, 2011, "Barbell Horn Ultrasonic Technology", Industrial Sonomechanics website, 2011, "Ultrasonic Liquid Processor Systems", Industrial Sonomechanics website, 2011, https://en.wikipedia.org/w/index.php?title=Ultrasonic_horn&oldid=820940378, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 17 January 2018, at 14:10. 1)Select the parents: parents, which are fit for reproduction, are selected for reproduction to generate offspring. We chose Continental Fence on the recommendation of a colleague and it was an excellent decision. For axial modes the length of the sonotrode is most important - increasing length will reduce the resonant frequency, and vice versa. Although the stepped-shaped horn has large amplitude, its maximum stress is also very large. In SonoAnalyzer the input is typically at the top of the sonotrode diagram in the Dimensions tab and the output at the bottom. 31) Is there a practical guide for ultrasonic transducers design? The profile of the horn is a cubic Bezier Curve. Table1 shows the comparison of advantages and disadvantages of commonly used horns. Fig. In ultrasonic systems the number of vibration cycles mounts up very quickly (eg. It allows you to create a land division between you and your neighbor. 1) Geometry; Through comparison, its obvious to judge that the vibration of the horn is longitudinal vibration, while bending vibration and torsional vibration are very small. When Auto tuning is used, the frequency display on the Dimensions tab becomes writable, and this is used to set the required working frequency. eg. 8 also lists the profile curves of these three horns. exponential) will often take some of the peaks out of the stress distribution, compared to a simple stepped sonotrode. [1] Ultrasonic processing of liquids relies of intense shear forces and extreme local conditions (temperatures up to 5000 K and pressures up to 1000 atm) generated by acoustic cavitation.[2]. 16 shows the frequency response curves of the horn in simulation and experiment. The horn is axisymmetric. Once they got to work on the actual installation, I knew they were the best contractors around with great value for my dollar. The objective function of the optimization design is: where f0 is the first-order resonant frequency acquired from each generation of calculation, M is the amplitude amplification ratio. In the frequency range of 0-100kHz, there are three longitudinal resonant frequencies in the system, including 53.87kHz, 63.80 kHz and 82.43kHz. The cubic Bezier Curve is determined by the following four points: starting point M0, control point of starting point M1, control point of end point M2 and end point M3, as shown in Fig. The starting point M0 and end point M3 are determined by the radiuses (R and r) of the top and end of the horn and its length L, while the curve shape is determined by the control point of starting point M1 and control point of end point M2. Piezoelectric ceramics (PZT-4), 7075-T651 aluminum, 303 stainless steel, and TC4. -The design of ultrasonic resonators with wide output crosssections  Fig. 4. Although stepped-shaped horn has large amplification coefficient of amplitude, it is prone to fracturing as it has larger stress due to its mutated cross-sectional area. The two are well consistent. Under the excitation voltage of 200Vp-p, the amplitude of the Bezier horn can reach 108m. Design of a 20 kHz cylindrical ultrasonic horn that can be tuned with the TRZ Analyzer. Schematic diagram of the experiment for ultrasonic horn. Flowchart of the optimization procedure. 1. 3. Fig. 1900 E Golf Road #950, Schaumburg, IL 60173. Comparison of the four types of the horns. Common design methods for horns include analytical method [1], equivalent circuit method [13] and equal mechanical impedance [14], transfer matrix method [15] and finite element method [16]. Over 20 years of quality fence building! 10. 2)Perform crossover and mutation operator on the selected parents: the algorithm uses simulated binary crossover and polynomial mutation. Some models have restrictions on geometry such that the output is always smaller (or at least, no bigger) than the input, so the step-up ratio will always be greater than or equal to one. Table 2. We use the latest tools and equipment to complete your projects on time and within budget. Fig. We take great pride that our skilled contractors provide guaranteed peace of mind and complete confidence in the quality of their work. A new horn with large amplitude is designed. Coming soon - worked examples of common sonotrode designs based on the principles described above. Commonly used horns mainly include stepped-shaped, conical, exponential and Gaussian-shaped [12] horns. So for example, if a transducer which delivers an amplitude of 10 microns is fitted to the input of a 2:1 booster, the amplitude at the output of the booster will be 20 microns. In the mesh generation, the element type of piezoelectric ceramic ring is 20-node hexahedral solid226, while other parts are 20-node hexahedral solid95. piezoelectric transducer ultrasonic sixth 9. Meanwhile, a conical horn with the same frequency is also processed. 8. For example in some designs increasing the length by 1 mm may reduce the frequency by about 150 Hz. You choose a design to start with based on experience (or just pure guesswork - the starting point doesn't really matter) and: This is very much like the real-life process of designing sonotrodes (without any computer aids) except that: Depending on the version and model chosen, SonoAnalyzer may offer to automate the frequency-tuning process described above. This does vary for different sonotrodes so treat it just as an initial figure - use your own results to find a suitable value for each new design. The front and back block as well as the bolt of Langevin vibrator are all made of ideal linear elastic materials. In SonoAnalyzer stresses are displayed individually for each mode on request. The amplitude of vibration is determined by the converter, booster ratio and sonotrode gain (geometry related). The horizontal ordinate is f=f-f0, and the vertical coordinates is amplitude amplification ratio, i.e., the ratio between the amplitudes at the top and the end of the horn. Designing horns by means of parameterization curve and finite element technology is a new design method [18]. The length L of the horn as well as the diameters of its top and end D1 and D2 were 53mm, 6.36mm and 1mm respectively. Longitudinal cross-sections of simple half-wavelength ultrasonic horns: 1 conical, 2 exponential or catenoidal, 3 - stepped. Comparison between the static and dynamic vibration, Fig. 3) Frequency and tolerance range. We are not only limited to fences, but. We also offer a huge selection of options for you to choose from during your fence installation in Schaumburg. This further verifies the reliability of the simulation results.

Fig. 4. Although stepped-shaped horn has large amplification coefficient of amplitude, it is prone to fracturing as it has larger stress due to its mutated cross-sectional area. The two are well consistent. Under the excitation voltage of 200Vp-p, the amplitude of the Bezier horn can reach 108m. Design of a 20 kHz cylindrical ultrasonic horn that can be tuned with the TRZ Analyzer. Schematic diagram of the experiment for ultrasonic horn. Flowchart of the optimization procedure. 1. 3. Fig. 1900 E Golf Road #950, Schaumburg, IL 60173. Comparison of the four types of the horns. Common design methods for horns include analytical method [1], equivalent circuit method [13] and equal mechanical impedance [14], transfer matrix method [15] and finite element method [16]. Over 20 years of quality fence building! 10. 2)Perform crossover and mutation operator on the selected parents: the algorithm uses simulated binary crossover and polynomial mutation. Some models have restrictions on geometry such that the output is always smaller (or at least, no bigger) than the input, so the step-up ratio will always be greater than or equal to one. Table 2. We use the latest tools and equipment to complete your projects on time and within budget. Fig. We take great pride that our skilled contractors provide guaranteed peace of mind and complete confidence in the quality of their work. A new horn with large amplitude is designed. Coming soon - worked examples of common sonotrode designs based on the principles described above. Commonly used horns mainly include stepped-shaped, conical, exponential and Gaussian-shaped [12] horns. So for example, if a transducer which delivers an amplitude of 10 microns is fitted to the input of a 2:1 booster, the amplitude at the output of the booster will be 20 microns. In the mesh generation, the element type of piezoelectric ceramic ring is 20-node hexahedral solid226, while other parts are 20-node hexahedral solid95. piezoelectric transducer ultrasonic sixth 9. Meanwhile, a conical horn with the same frequency is also processed. 8. For example in some designs increasing the length by 1 mm may reduce the frequency by about 150 Hz. You choose a design to start with based on experience (or just pure guesswork - the starting point doesn't really matter) and: This is very much like the real-life process of designing sonotrodes (without any computer aids) except that: Depending on the version and model chosen, SonoAnalyzer may offer to automate the frequency-tuning process described above. This does vary for different sonotrodes so treat it just as an initial figure - use your own results to find a suitable value for each new design. The front and back block as well as the bolt of Langevin vibrator are all made of ideal linear elastic materials. In SonoAnalyzer stresses are displayed individually for each mode on request. The amplitude of vibration is determined by the converter, booster ratio and sonotrode gain (geometry related). The horizontal ordinate is f=f-f0, and the vertical coordinates is amplitude amplification ratio, i.e., the ratio between the amplitudes at the top and the end of the horn. Designing horns by means of parameterization curve and finite element technology is a new design method [18]. The length L of the horn as well as the diameters of its top and end D1 and D2 were 53mm, 6.36mm and 1mm respectively. Longitudinal cross-sections of simple half-wavelength ultrasonic horns: 1 conical, 2 exponential or catenoidal, 3 - stepped. Comparison between the static and dynamic vibration, Fig. 3) Frequency and tolerance range. We are not only limited to fences, but. We also offer a huge selection of options for you to choose from during your fence installation in Schaumburg. This further verifies the reliability of the simulation results.  Fig. In SonoAnalyzer OE, the only models that offer auto tuning are the database-backed ones, ie. However, when the excitation frequency of the system approaches to 53.87 kHz, the second-order longitudinal frequency will not be excited. at the point of attachment the direction of motion is lateral or torsional, which a regular transducer should not be able to drive. Some boosters are reversible and in this case the step-up ratio is inverted - a 2:1 booster in reverse will work as a 1:2 step-down, or a step-up of 0.5. The frequency of the designed horn is 53.87kHz, while the experiment frequency is 53.167kHz. The horn is made to work under first-order longitudinal vibration mode by reasonably designing its shape. In genetic algorithm process, the number of generations N was set as 30, and the population of each generation was taken as 20. 14(b), the tracing and measurement for the marked point show the vibration displacement of the horn. If available this is shown at the foot of the Analysis tab - a selection box offering "Mode - frequency" (the default) or "Auto tuning". For quick service and reliable work, there simply isnt a better choice for homeowners in the greater Chicago area, from Evanston to Palatine, Deer Park to Mount Prospect, and Lake Zurich. 7. To develop a sonotrode, you should first establish the basic requisites: To avoid confusion while viewing the 3D display (which can be rotated to any orientation) the input surface is shown by a green-coloured region and the output is shown in orange. resonators ultrasonic krell engineering medical industrial cutting etc cauterizing disintegrating cavitating descaling scraping devices dental When the excitation voltage is 200Vp-p, the amplitude of the system can reach 108um. The working frequency of Langevin vibrator is 53.7 kHz, and it works under first-order longitudinal vibration mode. Metal inserts may be secured in plastic and dissimilar materials can often be bonded with proper tooling design. The horn with the maximum amplitude ratio under the frequency 53.7kHz was determined by means of genetic algorithm. They pointed out that the horns whose profiles were not straight lines often had higher amplitude compared with traditional horns.