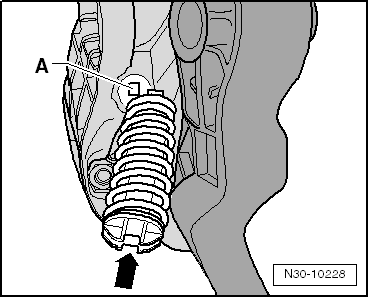

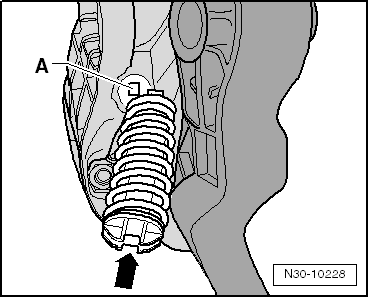

What are Spring Plungers and what are they used for? This article will look at six major types of spring plungers and what you can use them for. Spring plungers are indexing devices used for positioning and locking different components of equipment in place. is a mechanical device with a retractable nose. If you are installing equipment on softer materials like aluminum, plastic, or wood, then a press-fit plunger is your best bet. For this purpose, a magnet is integrated into the plunger pin that switches the sensor upon engaging after approx. The conventional indexing plunger is usually actuated with a pull button. They are ideal for constructing assembly fixtures and for positioning components on machine tools. work with different industrial applications like machine tools and woodwork equipment.  Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates. The plastic ribbed sleeve offers an aesthetically pleasing and comfortable finger grip. As the contact force puts pressure on the plunger or nose of the spring plunger, it depresses in to the body forcing the internal spring to compress allowing the contact force to position the nose into the desired notched out area. Indexing Plungers - Stainless Steel, Non Lock-Out/Lock-Out with Removable Pin, GN 817.8 Series. Plot No. Strong-enough side loads will force the plungers on devices equipped with rounded noses to retract. At norelem centring clamps with ball and hexagon segments or with wedges are available. To lock the plunger's tip into the desired position, simply release the ring. The wrench flats on the lock nut are exposed when the pin is retracted, so that the plunger can be easily tightened by means of an open end wrench. fastening and joining of parts and workpieces. The wrench flats on the lock nut are exposed when the pin is retracted, so that the plunger can be easily tightened by means of an open end wrench. Standard parts and machine elements can be fixed in a certain position using indexing plungers. Locking pins are used for quick fixing, connecting and locking of various parts and workpieces. Stubby plungers are used to stabilize, position and secure seat backs and tray tables on airliners. Mandrel collets are also available for holding in bores. With this extensive range, the right standard part for interlocking is always available for practically every type of application. As the name suggests, pull-pin spring plungers have a quick-release press-fit pull-pin body. You can use pull-pin spring plungers to retract and engage the plunger for locating, fastening quickly, and quick change operations. As sprung element, a ball or pin can be selected which are available in steel, stainless steel, ceramic or polyoxymethylene (POM). Vliers push-fit/press-fit plungers come with a plunger or ball nose and provide a quick, efficient installation process that saves time and cost. Standard spring plungers are used as a detent pin for fuel injection and weapon subsystems. Standard spring plungers are often used on cabin interiors. Along with a wide range of locating pins, norelem also offers additional positioning elements including centring pins, positioning pins or locating bushes. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. After retracting the plunger pin, turn the knob 30 degrees, release the knob and it will stay in the retracted position via the indexing lock. VILLCASE 3 PCS Plunger Latches Spring- Plunger Latches Spring- loaded Plunger Latches spring loaded locking pin Baby Bed Fastening, SBDs 'POP' Pull Pin | 1/2" Diameter Spring Loaded Plunger |1" Diameter x 1-1/2" Length Weld ON Steel Barrel | Hard Plastic T Handle Knob | Knurled Round Nut, heyous Push Fit Ball Nose Spring Plunger Stainless Steel Spring Return Knob Plunger Spring Indexing Plunger M10, GN 717-NI Series Stainless Steel Lock-Out Type Inch Size Indexing Plunger with Pull Knob, with Lock Nut, 3/8"-16 Thread Size, 0.63" Thread Length, GN 717-NI Series Stainless Steel Lock-Out Type Inch Size Indexing Plunger with Pull Knob, Without Lock Nut, 5/8"-11 Thread Size, 0.94" Thread Length, WN 717.10 Series Stainless Steel Non Lock-Out Type Stubby Hand Retractable Spring Plunger with Pull Ring, 3/8"-16 Thread, 0.44" Thread Length, LRSP Series Steel Lock-Out Type Hand Retractable Spring Plunger with Knurled Handle, Without Patch, 1/4"-20 Thread Size, 0.500" Thread Length, GN 722.2 Series Steel Type A Metric Size Square Spring Latches with Flange for Surface Mounting, Latch Position Right-Angled to Mounting Holes, Zinc Plated Finish, 10mm Item Diameter, 68mm Item Length, LRSP Series Steel Lock-Out Type Hand Retractable Spring Plunger with Knurled Handle, Without Patch, 3/8"-16 Thread Size, 0.750" Thread Length, J.W. Summary. Winco's range is very wide to cover many applications. Due to their versatility, spring-loaded plungers are commonly found in a host of industries, including defense, aerospace and automotive. Where defined bores are available for engaging the integrated pin, the positive connection typical of a pin is used. Compact indexing plunger. When you need to align, hold, or latch different parts of equipment together, you need a spring loaded device. Ball plungers are commonly used for notching and indexing where they are released with predetermined side loads.

Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates. The plastic ribbed sleeve offers an aesthetically pleasing and comfortable finger grip. As the contact force puts pressure on the plunger or nose of the spring plunger, it depresses in to the body forcing the internal spring to compress allowing the contact force to position the nose into the desired notched out area. Indexing Plungers - Stainless Steel, Non Lock-Out/Lock-Out with Removable Pin, GN 817.8 Series. Plot No. Strong-enough side loads will force the plungers on devices equipped with rounded noses to retract. At norelem centring clamps with ball and hexagon segments or with wedges are available. To lock the plunger's tip into the desired position, simply release the ring. The wrench flats on the lock nut are exposed when the pin is retracted, so that the plunger can be easily tightened by means of an open end wrench. fastening and joining of parts and workpieces. The wrench flats on the lock nut are exposed when the pin is retracted, so that the plunger can be easily tightened by means of an open end wrench. Standard parts and machine elements can be fixed in a certain position using indexing plungers. Locking pins are used for quick fixing, connecting and locking of various parts and workpieces. Stubby plungers are used to stabilize, position and secure seat backs and tray tables on airliners. Mandrel collets are also available for holding in bores. With this extensive range, the right standard part for interlocking is always available for practically every type of application. As the name suggests, pull-pin spring plungers have a quick-release press-fit pull-pin body. You can use pull-pin spring plungers to retract and engage the plunger for locating, fastening quickly, and quick change operations. As sprung element, a ball or pin can be selected which are available in steel, stainless steel, ceramic or polyoxymethylene (POM). Vliers push-fit/press-fit plungers come with a plunger or ball nose and provide a quick, efficient installation process that saves time and cost. Standard spring plungers are used as a detent pin for fuel injection and weapon subsystems. Standard spring plungers are often used on cabin interiors. Along with a wide range of locating pins, norelem also offers additional positioning elements including centring pins, positioning pins or locating bushes. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. After retracting the plunger pin, turn the knob 30 degrees, release the knob and it will stay in the retracted position via the indexing lock. VILLCASE 3 PCS Plunger Latches Spring- Plunger Latches Spring- loaded Plunger Latches spring loaded locking pin Baby Bed Fastening, SBDs 'POP' Pull Pin | 1/2" Diameter Spring Loaded Plunger |1" Diameter x 1-1/2" Length Weld ON Steel Barrel | Hard Plastic T Handle Knob | Knurled Round Nut, heyous Push Fit Ball Nose Spring Plunger Stainless Steel Spring Return Knob Plunger Spring Indexing Plunger M10, GN 717-NI Series Stainless Steel Lock-Out Type Inch Size Indexing Plunger with Pull Knob, with Lock Nut, 3/8"-16 Thread Size, 0.63" Thread Length, GN 717-NI Series Stainless Steel Lock-Out Type Inch Size Indexing Plunger with Pull Knob, Without Lock Nut, 5/8"-11 Thread Size, 0.94" Thread Length, WN 717.10 Series Stainless Steel Non Lock-Out Type Stubby Hand Retractable Spring Plunger with Pull Ring, 3/8"-16 Thread, 0.44" Thread Length, LRSP Series Steel Lock-Out Type Hand Retractable Spring Plunger with Knurled Handle, Without Patch, 1/4"-20 Thread Size, 0.500" Thread Length, GN 722.2 Series Steel Type A Metric Size Square Spring Latches with Flange for Surface Mounting, Latch Position Right-Angled to Mounting Holes, Zinc Plated Finish, 10mm Item Diameter, 68mm Item Length, LRSP Series Steel Lock-Out Type Hand Retractable Spring Plunger with Knurled Handle, Without Patch, 3/8"-16 Thread Size, 0.750" Thread Length, J.W. Summary. Winco's range is very wide to cover many applications. Due to their versatility, spring-loaded plungers are commonly found in a host of industries, including defense, aerospace and automotive. Where defined bores are available for engaging the integrated pin, the positive connection typical of a pin is used. Compact indexing plunger. When you need to align, hold, or latch different parts of equipment together, you need a spring loaded device. Ball plungers are commonly used for notching and indexing where they are released with predetermined side loads.  For example, they are routinely used in commercial and military aircraft. Winco offers a comprehensive range of pins. Cycle life depends on the design of the plunger and the environment. Spring-loaded devices are commonly used in applications that require positioning and securing, indexing, locating, quick disconnects and ejecting, positive locking, latching and more. A ball lock pin is composed of three main components: the grip with push button, a pin and the balls. This site requires you to register or login to post a comment. You can use them as shock absorbers or ejectors by applying accurate and repeatable spring end forces through a ball or rounded nose, especially in sheet metalworking. You should also consider the force of a spring-loaded device as part of your purchasing criteria that is, whether it exerts light, standard, or heavy end-force on equipment. This way, the spring plunger can lock a component into a specific placement. Type C offers a lock-out position for applications that require the plunger pin to be retracted for an extended period of time. SBDs (Pack of 4) 'POP' Pull Pin 1" Diameter x 1-1/2" Length Weld ON Steel Barrel | 1/2" Diameter Spring Loaded Zinc Plated Steel Plunger | Plastic T Handle Knob | Knurled Round Nut w/Grub Screw Lock. This is termed a cycle. Copyright MISUMI Corporation All Rights Reserved. Pull spring plungers are best for adjustable tubing, tooling, latches, fixtures, gates, and similar equipment.

For example, they are routinely used in commercial and military aircraft. Winco offers a comprehensive range of pins. Cycle life depends on the design of the plunger and the environment. Spring-loaded devices are commonly used in applications that require positioning and securing, indexing, locating, quick disconnects and ejecting, positive locking, latching and more. A ball lock pin is composed of three main components: the grip with push button, a pin and the balls. This site requires you to register or login to post a comment. You can use them as shock absorbers or ejectors by applying accurate and repeatable spring end forces through a ball or rounded nose, especially in sheet metalworking. You should also consider the force of a spring-loaded device as part of your purchasing criteria that is, whether it exerts light, standard, or heavy end-force on equipment. This way, the spring plunger can lock a component into a specific placement. Type C offers a lock-out position for applications that require the plunger pin to be retracted for an extended period of time. SBDs (Pack of 4) 'POP' Pull Pin 1" Diameter x 1-1/2" Length Weld ON Steel Barrel | 1/2" Diameter Spring Loaded Zinc Plated Steel Plunger | Plastic T Handle Knob | Knurled Round Nut w/Grub Screw Lock. This is termed a cycle. Copyright MISUMI Corporation All Rights Reserved. Pull spring plungers are best for adjustable tubing, tooling, latches, fixtures, gates, and similar equipment.  How do spring plungers work? This product family includes the following positioning elements: Lateral spring plungers are used to position, clamp, hold or secure workpieces and components. In the resting position, or full travel position, the plunger is extended. 2. Our service team is available from Monday to Friday between 7:30 AM and 5:00 PM Central Time. Leading manufacturers of spring-loaded plungers continue to explore new materials and designs that lend themselves to new manufacturing processes and creating parts for different industries, including IIoT. Each provides different benefits. They are used in fixtures and machine tools, e.g. At this stage, you should ask questions like, What is the installation process for this plunger? What is the plungers thread length and thread size? and what can this device do?. You can also use these devices as some form of support between objects or to eject a component from its groove. Pressing the spring-loaded push button unlocks both balls, and releasing it locks the balls again. It can be pushed back into the body of the device when force on the plunger exceeds the spring force being applied. Your recently viewed items and featured recommendations, Select the department you want to search in. On the other hand, a spring lever is a mechanical tool that allows you to fix a component into a specific position. When the cam action indexing plungers are positioned symmetrically, the left or right-handed types allow for a practical, i.e. After welding, the indexing plunger is then assembled. For one, they can serve as some type of cushion between two objects. This type of plunger allows for swift one-handed operations. Before purchasing any type of spring plunger, you should ensure that it is suitable for your equipment. Spring-loaded devices will continue to help companies bring products to market faster and with more reliable performance and added functions. Press Fit Spring Plungers GN 822.1 Mini Indexing Plungers Steel, Lock-Out and Non Lock-Out, with Open Lock Mechanism. These types of spring plungers are made from steel, thermoplastic, technopolymer, or stainless steel. By your continued use of this site you accept such use. Stubby plungers are more compact, making them a good choice for applications with limited space. This in turn allows for a little space between two objects. Pull Pin Spring Plungers Spring plungers can also be used as a form of cushion between two objects. JW Winco has its own in-house machining facility; this provides an advantage for our customers to take an idea and create a unique customized solution through the choice of using one of our standard parts. They are designed for installation in thin walled sheet metal applications. GN 413 indexing plungers, due to its shape, the pull ring can be used both as a screw-in aid during assembly, and to retract the plunger pin for positioning or locking the pin in the retracted position(Type C / CK).Lock-out types C / CK are used for applications where the plunger pin needs to stay in its retracted position. Ball Plungers have no knob and a ball instead of a nose. Side loadings are used to activate spring-loaded devices in indexing, positioning and detenting operations. Type B is non lock-out type.

How do spring plungers work? This product family includes the following positioning elements: Lateral spring plungers are used to position, clamp, hold or secure workpieces and components. In the resting position, or full travel position, the plunger is extended. 2. Our service team is available from Monday to Friday between 7:30 AM and 5:00 PM Central Time. Leading manufacturers of spring-loaded plungers continue to explore new materials and designs that lend themselves to new manufacturing processes and creating parts for different industries, including IIoT. Each provides different benefits. They are used in fixtures and machine tools, e.g. At this stage, you should ask questions like, What is the installation process for this plunger? What is the plungers thread length and thread size? and what can this device do?. You can also use these devices as some form of support between objects or to eject a component from its groove. Pressing the spring-loaded push button unlocks both balls, and releasing it locks the balls again. It can be pushed back into the body of the device when force on the plunger exceeds the spring force being applied. Your recently viewed items and featured recommendations, Select the department you want to search in. On the other hand, a spring lever is a mechanical tool that allows you to fix a component into a specific position. When the cam action indexing plungers are positioned symmetrically, the left or right-handed types allow for a practical, i.e. After welding, the indexing plunger is then assembled. For one, they can serve as some type of cushion between two objects. This type of plunger allows for swift one-handed operations. Before purchasing any type of spring plunger, you should ensure that it is suitable for your equipment. Spring-loaded devices will continue to help companies bring products to market faster and with more reliable performance and added functions. Press Fit Spring Plungers GN 822.1 Mini Indexing Plungers Steel, Lock-Out and Non Lock-Out, with Open Lock Mechanism. These types of spring plungers are made from steel, thermoplastic, technopolymer, or stainless steel. By your continued use of this site you accept such use. Stubby plungers are more compact, making them a good choice for applications with limited space. This in turn allows for a little space between two objects. Pull Pin Spring Plungers Spring plungers can also be used as a form of cushion between two objects. JW Winco has its own in-house machining facility; this provides an advantage for our customers to take an idea and create a unique customized solution through the choice of using one of our standard parts. They are designed for installation in thin walled sheet metal applications. GN 413 indexing plungers, due to its shape, the pull ring can be used both as a screw-in aid during assembly, and to retract the plunger pin for positioning or locking the pin in the retracted position(Type C / CK).Lock-out types C / CK are used for applications where the plunger pin needs to stay in its retracted position. Ball Plungers have no knob and a ball instead of a nose. Side loadings are used to activate spring-loaded devices in indexing, positioning and detenting operations. Type B is non lock-out type.  When the pin is retracted to its end position, the knurled knob engages with a clearly audible click. Shop products from small business brands sold in Amazons store. A few examples include: Defense. To view the page correctly and to be able to use all functions, please enable JavaScript in your browser. maxo, Micro 3D Printing Helps Fabricate Microwells for Microgravity, Researchers from the Buchmann Institute for Molecular Life Sciences at Goethe University in Frankfurt am Main, Germany have used the microArch S140,, The future of digitalization: On-premises vs. cloud, Recently Tosh Tambe, VP, Cloud Strategy and Transformation and Chad Jackson, Chief Analyst and CEO of Lifecycle Insights, had a conversation regardin. Spring thrust pads are generally used as pressure pins in applications. Youre seeing this ad based on the products relevance to your search query. When the force on the plunger is reduced, the spring extends the plunger once again. Pull Pin - Round Handle - 3/8" Dia Plunger -3" Length x 1" Diameter Weldon Steel Barrel -Spring Loaded Plunger -Universal Fitness Equipment Adjustment Knob. Press fit plungers exert a heavy spring force and mostly have steel bodies. Designing machinery may not be the most artistic pursuit in the world, but sometimes the issue of color can be essential even in industrial design. For example, plungers are easier to install and offer a single assembly that replaces several components. Returns to its original position via internal spring action, Mini Indexing Plungers - Stainless Steel, Non Lock-Out/Lock-Out, with Hidden Lock Mechanism, Plate Mount, GN 822.9Series. For example, an indexing plunger without a knob comes with a pull ring or threaded pin, while the lock and clamp versions merge clamping functions with the primary indexing function. If required, the indexing pins can be machined or made by the user as shown in the drawing above. What are ball plungers? Indexing Lever Plungers (Stainless Steel) ILP-Sus. In this article we will take a closer look at: 1. Locating pins belong to the classic positioning elements. Spring-loaded plungers use a spring and a plunger (or ball tip) to exert a precise and repeatable force. Cam action indexing plungers are a modified variant of the indexing plungers. GN 822 Mini Indexing Plungers Steel, Lock-Out and Non Lock-Out Types, with Hidden Lock Mechanism. The ball lock pins from norelem are available with a wide range of different grips. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. Spring-loaded plungers can handle from one to several thousand cycles. GN 817.6 indexing plungers with sensor for position monitoring allow for electronic monitoring of the plunger pin state. Ball plungers often require a slot or hex head screwdriver for installation. Indexing plungers are used to lock or index machine elements. 6W14L90 and 8W18L90), the pin does not fully retract. They are a better option than having engineers cobble together an assembly that uses a simple, standard spring and plunger nose to do that same task. At Reid Supply, we stock different spring plungers plus other accessories and mechanical tools, including cam levers, handwheels, and toggle clamps. GN 822.1 indexing plungers feature small, compact dimensions. To prevent faults, no external magnetic fields should be acting on the indexing plunger. You can also opt for precision indexing plungers, lock and clamp indexing plungers or an indexing plunger without a knob. Fax +49 71 45/206-83, Cardan single joints, stainless steel, with plain bearing, similar to DIN 808, Cardan double joints, stainless steel, with plain bearing, similar to DIN 808, Stainless steel hinges with fastening screws, Thread cover, stainless steel, in Hygienic DESIGN, Indexing plungers steel or stainless steel with status sensor, hardwired, Hex cap nut, high style DIN 1587 steel or stainless steel, Hex cap nut, low style DIN 917 steel or stainless steel, Hook clamp with collar and clamping lever with clamping force intensifier, Hook clamp with collar with long clamping claw, Mechanical position switch plastic housing. Thomas Foley is general manager at Vlier Inc., a company that makes mechanical components such as spring plungers, quick releases and leveling devices found in aerospace platforms, credit card readers, medical instruments, rollercoasters and high-speed rail. Push-fits can be manually installed easily and feature a flanged body to ensure consistent force delivery. This body is threaded into the application while the ring pokes out to the outer surface. You can attach knobs, grips, prisms and other types of inserts to the plunger via the tapped hole. A mechanism in the plunger withdraws an indexing pin from a hole in a counterpart enabling connections machine elements to be quickly and easily locked or released. Discover more about the small businesses partnering with Amazon and Amazons commitment to empowering them. Eccentric stops, adjustable screw stops or 5D workpiece stops norelem offers a wide range of stops. When a trigger is pushed the nose and spring are then forced back into starting position forcing the element out of the grove. When a spring plunger comes in contact with some degree of force, this pressure compresses its in-built spring and moves the nose into the desired position. It is used in machine and fixture applications to lock items in place, especially when indexing a range of motion or a series of positions. For one, they can serve as some type of cushion between two objects. 2990 Technology Dr At Reid Supply, we stock different spring plungers plus other, and mechanical tools, including cam levers, handwheels, and toggle clamps. When the button is released again, the pin locks automatically as the balls are pushed out. They also have fixed-in hexagonal tapped pins that can be used for thrust or traction. By exerting some degree of pressure on their ball or nose, spring plungers keep the components in the same position. The delivered force is affected by the mechanisms travel (range or motion), with the force increasing as the spring is compressed. GN 608.1 indexing plunger is used in applications which require surface mounting, and the plunger has to stay in its retracted position. > How do Spring Plungers work? All the information you need about news from JW Winco! If you are installing equipment on softer materials like aluminum, plastic, or wood, then a. have a quick-release press-fit pull-pin body. This body is threaded into the application while the ring pokes out to the outer surface. Plungers can be installed using threads and push-fit or press-fit designs. is a spring-loaded device that has a ball on its tip. For more information, please see our privacy policy. machine construction to secure pivoting or rotating parts. Aerospace. To lock the plunger's tip into the desired position, simply release the ring. Most ball plungers have a thread locking element that keeps them in place after their installation. In the rest position, the lock-out mechanism is completely concealed by the knob. The component can also be clamped with a positive down force. Spring plungers have many uses. The plastic ribbed sleeve offers an aesthetically pleasing and comfortable finger grip. GN 822.9 mini indexing plungers feature small, compact dimensions. To achieve this, the knob is rotated by 90 degrees after being retracted. The locking function is simple, useful and functional. Price and other details may vary based on product size and color. Phenolic and Delrin nose plungers are used in drivetrains and steering components, as well as seat positioners. GN 414.1 safety lock indexing plungers with click-type lock are used when the plunger pin is to be briefly prevented from protruding. The spring plunger nose depresses as it comes in contact with an object and pushes out until that object is lined up in position with the object next to it. The product range from norelem includes lateral spring plungers with or without threaded sleeve and an offset bush cam for holding and positioning the spring plungers. Clamping indexing plungers are used for positioning, securing and clamping adjusting elements at the same time. are made of brass, steel, or stainless steel for protection against corrosion. GN 817.8 indexing plungers have been designed so that special versions of the indexing pins can be made economically in smaller unit quantities. Our handbook has the most comprehensive number of standard parts with over 75,000 items on 2,184 pages. In contrast to conventional spring plungers, lateral spring plungers apply the force horizontally to the thrust pin. The UCI World Cup is about t twitter.com/i/web/status/1. The spring keeps constant pressure on the plunger when it is in the resting position. Spring-loaded plungers arent always the right choice. Visit our website today to browse through our new products and see if anyone is the right fit for your workpiece. Indexing Plungers All parts are supplied individually as a disassembled set. A ball plunger is a spring-loaded device that has a ball on its tip. Spring plungers are often used in machine construction or toolmaking as indexing elements or ejector pins. The limit stop provides a safety feature whereby the lever arm can not be turned by more than 180.The notch on GN 721.6 cam action indexing plungers allows for safe positioning while the plunger pin is held in the retracted position. An indexing plunger is a mechanical device with a retractable nose. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. Workpieces can be optimally clamped or positioned using centring clamps. Rochester Hills, MI 48309. Indexing Plungers - Stainless Steel, with Sensor for Position Monitoring, GN 817.6 Series. These mechanical devices consist of the housing barrel and plunger assembly. Fax +49 (0) 74 54 / 793-33, Clamping levers, tension levers, cam levers, Pull handles, tubular handles, recessed handles, Handwheels, crank handles, position indicators, Quarter-turn locks, edge protection profiles, Support elements, locating elements, stop elements, Stainless steel hinges with fastening screws, Thread cover, stainless steel, in Hygienic DESIGN, Hex cap nut, low style DIN 917 steel or stainless steel, Hex cap nut, high style DIN 1587 steel or stainless steel, Hook clamp with collar and clamping lever with clamping force intensifier, Hook clamp with collar with long clamping claw, Indexing plunger, stainless steel with remote actuation, Retaining washers for quarter turn latches, Lock bottom parts for quarter turn latches, Aluminium cap for holes and screw heads with hex socket, Hook clamp with extended clamping claw, with mounting bracket, Clevises with screw, steel or stainless steel. This device can have 10-32 to 1-8 threads plus a piano or stainless steel wire thread, depending on the type. aB max. Other advantages of centring clamps are the low structural height and the wide adjustment range. JW Winco offers a wide range of Indexing, Ball and Spring Plungers. This device can have 10-32 to 1-8 threads plus a piano or stainless steel wire thread, depending on the type. Spring plungers are used for locking and then locating of separate components and come in a variety of metric and standard sizes. Spring plungers have many uses. 6W14L62 and 8W18L62), the pin does not fully retract. MIT Develops 3D-printed Plasma Sensors for Satellites, NASA Plans Roundtrip Mission to Mars to Bring Soil Samples to Earth, 6 Amazing Ways IoT is Shaping Trucking for the Long Haul, Discover Festo Round Cylinders DSNU-S and DSNU, White paper Compressed air preparation in pneumatics. Plungers are inserted into position by holding them by the knurled knob. Thread spring plungers have enclosed springs in threaded capsules. Plungers come in a variety of thread sizes to fit most applications. Operation of the plunger is carried out by three types of movement.Standard Models (PDV-A, PDV-AK)Pin retracts into the body when the lever is rotated 90Force from the internal spring returns the pin to its original position when the lever is releasedHolding Models (PDV-B, PDV-BK)Pin does not retract when the lever is released at a position of 120Force from the internal spring returns the pin to its original position when the lever is rotated slightly in the opposite directionLocking Models (PDV-C, PDV-CK)Pin retracts into the body when the lever is rotated 120When the pin is retracted, the guide pin is locked inside the slotPin can be unlocked by slightly pulling on the lever while rotating it in the opposite directionForce from the internal spring returns the pin to its original position when the lever is rotated slightlyPDV-A, PDV-B, and PDV-C has no lock nut and can be used to prevent looseningPDV-AK, PDV-BK, and PDV-CK have lock nuts and can be used to fix pins in place, Cam Action Indexing Plungers - Stainless Steel, Lock-Out, with 180 Limit Stop, GN 721.6Series. The lock can be released by turning the bolt. Plungers also streamline the process of setting up manufacturing lines and tooling. The push button has a spring mechanism which ensures that the pin is disengaged by retracting the balls. Their diameters can be anything from one-eight of an inch to half-inch. If the latch pin may need to be retracted periodically, the notch allows for safe positioning while the latch pin is held in the retracted position. GN 612.2 the cam action indexing plungers are best utilized when the pin needs to be retracted. It is used in machine and fixture applications to lock items in place, especially when indexing a range of motion or a series of positions. A notch keeps the plunger in the retracted position. Please note that for these longer pin lengths (part nos. https://www.facebook.com/MachineDesignMagazine/, https://www.linkedin.com/company/10998894. 2022 Endeavor Business Media, LLC. A spring plunger isn't a one-size-fits-all tool, which means you have many options to choose from, depending on your needs and how well they answer the questions listed above. 2/3 of the stroke l1.The sensor electronics then outputs a high signal, e.g. Also called two-way spring plungers, push pin spring plungers are used to engage, position, or clamp various components. GN 612.2 indexing plungers feature a counterbored flange for surface mounting. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. All rights reserved. A number of our metal parts can be produced in a variety of colors using a powder coating process. It moves in and out of position, and is often used in rolling and detent applications. All you have to do is twist the handle 90 degrees, and it will lock the plunger in. Click Here, Headquarters in Metalworking Ball Nose Spring Plungers, 2 Packs Spring Plunger with Pull Ring, 1/4"- 20 Thread Size, 0.31" Thread Length, Stainless Steel Non-Locking Type Stubby Hand-Retractable Spring Plunger Index Plunger, PSCCO Positioning Pin Series Steel Lock-Out Type Hand Retractable Spring Plunger with L Handle, VictorsHome Push Plunger Lock 19mm x 32mm Cylinder Head Chrome Plated Zinc Alloy Keyed Alike 2 Pack, GN 822 Series Stainless Steel Lock-Out Type C Mini Indexing Plunger with Hidden Lock Mechanism, M8 x .75mm Thread Size, 5mm Thread Length, 4mm Item Diameter. The larger ones, however, might not fit in tight spaces. The norelem product range includes indexing plungers with different pin lengths, diameters and materials. A cam lever or clamp is a simple fastening device used for releasing equipment from its fixed position. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. Shelving, Rack-Decking & Bulk-Handling Carts, Secondary Containment & Propane Tank Storage, Lifting Magnets, Vacuum Cups & Accessories. Updated: 8/5/2020, Our Spring Plungers & Pins Spring Plungers & Pins Blog Section They can be designed to exert a specific level of force and apply it in detenting, indexing or locating operations. 5. Every pin types is available in a variety of materials. Engineers can choose the style that best meets installation requirements and client preferences.

When the pin is retracted to its end position, the knurled knob engages with a clearly audible click. Shop products from small business brands sold in Amazons store. A few examples include: Defense. To view the page correctly and to be able to use all functions, please enable JavaScript in your browser. maxo, Micro 3D Printing Helps Fabricate Microwells for Microgravity, Researchers from the Buchmann Institute for Molecular Life Sciences at Goethe University in Frankfurt am Main, Germany have used the microArch S140,, The future of digitalization: On-premises vs. cloud, Recently Tosh Tambe, VP, Cloud Strategy and Transformation and Chad Jackson, Chief Analyst and CEO of Lifecycle Insights, had a conversation regardin. Spring thrust pads are generally used as pressure pins in applications. Youre seeing this ad based on the products relevance to your search query. When the force on the plunger is reduced, the spring extends the plunger once again. Pull Pin - Round Handle - 3/8" Dia Plunger -3" Length x 1" Diameter Weldon Steel Barrel -Spring Loaded Plunger -Universal Fitness Equipment Adjustment Knob. Press fit plungers exert a heavy spring force and mostly have steel bodies. Designing machinery may not be the most artistic pursuit in the world, but sometimes the issue of color can be essential even in industrial design. For example, plungers are easier to install and offer a single assembly that replaces several components. Returns to its original position via internal spring action, Mini Indexing Plungers - Stainless Steel, Non Lock-Out/Lock-Out, with Hidden Lock Mechanism, Plate Mount, GN 822.9Series. For example, an indexing plunger without a knob comes with a pull ring or threaded pin, while the lock and clamp versions merge clamping functions with the primary indexing function. If required, the indexing pins can be machined or made by the user as shown in the drawing above. What are ball plungers? Indexing Lever Plungers (Stainless Steel) ILP-Sus. In this article we will take a closer look at: 1. Locating pins belong to the classic positioning elements. Spring-loaded plungers use a spring and a plunger (or ball tip) to exert a precise and repeatable force. Cam action indexing plungers are a modified variant of the indexing plungers. GN 822 Mini Indexing Plungers Steel, Lock-Out and Non Lock-Out Types, with Hidden Lock Mechanism. The ball lock pins from norelem are available with a wide range of different grips. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. Spring-loaded plungers can handle from one to several thousand cycles. GN 817.6 indexing plungers with sensor for position monitoring allow for electronic monitoring of the plunger pin state. Ball plungers often require a slot or hex head screwdriver for installation. Indexing plungers are used to lock or index machine elements. 6W14L90 and 8W18L90), the pin does not fully retract. They are a better option than having engineers cobble together an assembly that uses a simple, standard spring and plunger nose to do that same task. At Reid Supply, we stock different spring plungers plus other accessories and mechanical tools, including cam levers, handwheels, and toggle clamps. GN 822.1 indexing plungers feature small, compact dimensions. To prevent faults, no external magnetic fields should be acting on the indexing plunger. You can also opt for precision indexing plungers, lock and clamp indexing plungers or an indexing plunger without a knob. Fax +49 71 45/206-83, Cardan single joints, stainless steel, with plain bearing, similar to DIN 808, Cardan double joints, stainless steel, with plain bearing, similar to DIN 808, Stainless steel hinges with fastening screws, Thread cover, stainless steel, in Hygienic DESIGN, Indexing plungers steel or stainless steel with status sensor, hardwired, Hex cap nut, high style DIN 1587 steel or stainless steel, Hex cap nut, low style DIN 917 steel or stainless steel, Hook clamp with collar and clamping lever with clamping force intensifier, Hook clamp with collar with long clamping claw, Mechanical position switch plastic housing. Thomas Foley is general manager at Vlier Inc., a company that makes mechanical components such as spring plungers, quick releases and leveling devices found in aerospace platforms, credit card readers, medical instruments, rollercoasters and high-speed rail. Push-fits can be manually installed easily and feature a flanged body to ensure consistent force delivery. This body is threaded into the application while the ring pokes out to the outer surface. You can attach knobs, grips, prisms and other types of inserts to the plunger via the tapped hole. A mechanism in the plunger withdraws an indexing pin from a hole in a counterpart enabling connections machine elements to be quickly and easily locked or released. Discover more about the small businesses partnering with Amazon and Amazons commitment to empowering them. Eccentric stops, adjustable screw stops or 5D workpiece stops norelem offers a wide range of stops. When a trigger is pushed the nose and spring are then forced back into starting position forcing the element out of the grove. When a spring plunger comes in contact with some degree of force, this pressure compresses its in-built spring and moves the nose into the desired position. It is used in machine and fixture applications to lock items in place, especially when indexing a range of motion or a series of positions. For one, they can serve as some type of cushion between two objects. 2990 Technology Dr At Reid Supply, we stock different spring plungers plus other, and mechanical tools, including cam levers, handwheels, and toggle clamps. When the button is released again, the pin locks automatically as the balls are pushed out. They also have fixed-in hexagonal tapped pins that can be used for thrust or traction. By exerting some degree of pressure on their ball or nose, spring plungers keep the components in the same position. The delivered force is affected by the mechanisms travel (range or motion), with the force increasing as the spring is compressed. GN 608.1 indexing plunger is used in applications which require surface mounting, and the plunger has to stay in its retracted position. > How do Spring Plungers work? All the information you need about news from JW Winco! If you are installing equipment on softer materials like aluminum, plastic, or wood, then a. have a quick-release press-fit pull-pin body. This body is threaded into the application while the ring pokes out to the outer surface. Plungers can be installed using threads and push-fit or press-fit designs. is a spring-loaded device that has a ball on its tip. For more information, please see our privacy policy. machine construction to secure pivoting or rotating parts. Aerospace. To lock the plunger's tip into the desired position, simply release the ring. Most ball plungers have a thread locking element that keeps them in place after their installation. In the rest position, the lock-out mechanism is completely concealed by the knob. The component can also be clamped with a positive down force. Spring plungers have many uses. The plastic ribbed sleeve offers an aesthetically pleasing and comfortable finger grip. GN 822.9 mini indexing plungers feature small, compact dimensions. To achieve this, the knob is rotated by 90 degrees after being retracted. The locking function is simple, useful and functional. Price and other details may vary based on product size and color. Phenolic and Delrin nose plungers are used in drivetrains and steering components, as well as seat positioners. GN 414.1 safety lock indexing plungers with click-type lock are used when the plunger pin is to be briefly prevented from protruding. The spring plunger nose depresses as it comes in contact with an object and pushes out until that object is lined up in position with the object next to it. The product range from norelem includes lateral spring plungers with or without threaded sleeve and an offset bush cam for holding and positioning the spring plungers. Clamping indexing plungers are used for positioning, securing and clamping adjusting elements at the same time. are made of brass, steel, or stainless steel for protection against corrosion. GN 817.8 indexing plungers have been designed so that special versions of the indexing pins can be made economically in smaller unit quantities. Our handbook has the most comprehensive number of standard parts with over 75,000 items on 2,184 pages. In contrast to conventional spring plungers, lateral spring plungers apply the force horizontally to the thrust pin. The UCI World Cup is about t twitter.com/i/web/status/1. The spring keeps constant pressure on the plunger when it is in the resting position. Spring-loaded plungers arent always the right choice. Visit our website today to browse through our new products and see if anyone is the right fit for your workpiece. Indexing Plungers All parts are supplied individually as a disassembled set. A ball plunger is a spring-loaded device that has a ball on its tip. Spring plungers are often used in machine construction or toolmaking as indexing elements or ejector pins. The limit stop provides a safety feature whereby the lever arm can not be turned by more than 180.The notch on GN 721.6 cam action indexing plungers allows for safe positioning while the plunger pin is held in the retracted position. An indexing plunger is a mechanical device with a retractable nose. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. Workpieces can be optimally clamped or positioned using centring clamps. Rochester Hills, MI 48309. Indexing Plungers - Stainless Steel, with Sensor for Position Monitoring, GN 817.6 Series. These mechanical devices consist of the housing barrel and plunger assembly. Fax +49 (0) 74 54 / 793-33, Clamping levers, tension levers, cam levers, Pull handles, tubular handles, recessed handles, Handwheels, crank handles, position indicators, Quarter-turn locks, edge protection profiles, Support elements, locating elements, stop elements, Stainless steel hinges with fastening screws, Thread cover, stainless steel, in Hygienic DESIGN, Hex cap nut, low style DIN 917 steel or stainless steel, Hex cap nut, high style DIN 1587 steel or stainless steel, Hook clamp with collar and clamping lever with clamping force intensifier, Hook clamp with collar with long clamping claw, Indexing plunger, stainless steel with remote actuation, Retaining washers for quarter turn latches, Lock bottom parts for quarter turn latches, Aluminium cap for holes and screw heads with hex socket, Hook clamp with extended clamping claw, with mounting bracket, Clevises with screw, steel or stainless steel. This device can have 10-32 to 1-8 threads plus a piano or stainless steel wire thread, depending on the type. aB max. Other advantages of centring clamps are the low structural height and the wide adjustment range. JW Winco offers a wide range of Indexing, Ball and Spring Plungers. This device can have 10-32 to 1-8 threads plus a piano or stainless steel wire thread, depending on the type. Spring plungers are used for locking and then locating of separate components and come in a variety of metric and standard sizes. Spring plungers have many uses. 6W14L62 and 8W18L62), the pin does not fully retract. MIT Develops 3D-printed Plasma Sensors for Satellites, NASA Plans Roundtrip Mission to Mars to Bring Soil Samples to Earth, 6 Amazing Ways IoT is Shaping Trucking for the Long Haul, Discover Festo Round Cylinders DSNU-S and DSNU, White paper Compressed air preparation in pneumatics. Plungers are inserted into position by holding them by the knurled knob. Thread spring plungers have enclosed springs in threaded capsules. Plungers come in a variety of thread sizes to fit most applications. Operation of the plunger is carried out by three types of movement.Standard Models (PDV-A, PDV-AK)Pin retracts into the body when the lever is rotated 90Force from the internal spring returns the pin to its original position when the lever is releasedHolding Models (PDV-B, PDV-BK)Pin does not retract when the lever is released at a position of 120Force from the internal spring returns the pin to its original position when the lever is rotated slightly in the opposite directionLocking Models (PDV-C, PDV-CK)Pin retracts into the body when the lever is rotated 120When the pin is retracted, the guide pin is locked inside the slotPin can be unlocked by slightly pulling on the lever while rotating it in the opposite directionForce from the internal spring returns the pin to its original position when the lever is rotated slightlyPDV-A, PDV-B, and PDV-C has no lock nut and can be used to prevent looseningPDV-AK, PDV-BK, and PDV-CK have lock nuts and can be used to fix pins in place, Cam Action Indexing Plungers - Stainless Steel, Lock-Out, with 180 Limit Stop, GN 721.6Series. The lock can be released by turning the bolt. Plungers also streamline the process of setting up manufacturing lines and tooling. The push button has a spring mechanism which ensures that the pin is disengaged by retracting the balls. Their diameters can be anything from one-eight of an inch to half-inch. If the latch pin may need to be retracted periodically, the notch allows for safe positioning while the latch pin is held in the retracted position. GN 612.2 the cam action indexing plungers are best utilized when the pin needs to be retracted. It is used in machine and fixture applications to lock items in place, especially when indexing a range of motion or a series of positions. A notch keeps the plunger in the retracted position. Please note that for these longer pin lengths (part nos. https://www.facebook.com/MachineDesignMagazine/, https://www.linkedin.com/company/10998894. 2022 Endeavor Business Media, LLC. A spring plunger isn't a one-size-fits-all tool, which means you have many options to choose from, depending on your needs and how well they answer the questions listed above. 2/3 of the stroke l1.The sensor electronics then outputs a high signal, e.g. Also called two-way spring plungers, push pin spring plungers are used to engage, position, or clamp various components. GN 612.2 indexing plungers feature a counterbored flange for surface mounting. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. All rights reserved. A number of our metal parts can be produced in a variety of colors using a powder coating process. It moves in and out of position, and is often used in rolling and detent applications. All you have to do is twist the handle 90 degrees, and it will lock the plunger in. Click Here, Headquarters in Metalworking Ball Nose Spring Plungers, 2 Packs Spring Plunger with Pull Ring, 1/4"- 20 Thread Size, 0.31" Thread Length, Stainless Steel Non-Locking Type Stubby Hand-Retractable Spring Plunger Index Plunger, PSCCO Positioning Pin Series Steel Lock-Out Type Hand Retractable Spring Plunger with L Handle, VictorsHome Push Plunger Lock 19mm x 32mm Cylinder Head Chrome Plated Zinc Alloy Keyed Alike 2 Pack, GN 822 Series Stainless Steel Lock-Out Type C Mini Indexing Plunger with Hidden Lock Mechanism, M8 x .75mm Thread Size, 5mm Thread Length, 4mm Item Diameter. The larger ones, however, might not fit in tight spaces. The norelem product range includes indexing plungers with different pin lengths, diameters and materials. A cam lever or clamp is a simple fastening device used for releasing equipment from its fixed position. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. Shelving, Rack-Decking & Bulk-Handling Carts, Secondary Containment & Propane Tank Storage, Lifting Magnets, Vacuum Cups & Accessories. Updated: 8/5/2020, Our Spring Plungers & Pins Spring Plungers & Pins Blog Section They can be designed to exert a specific level of force and apply it in detenting, indexing or locating operations. 5. Every pin types is available in a variety of materials. Engineers can choose the style that best meets installation requirements and client preferences.  The dimensional tolerances between latch pin and body are selected so that the functional reliability is guaranteed even after welding, applying a corrosion protection layer, or in case of contamination. If you want to free a component from the plunger's fixed position, you only have to pull the device's handle. By exerting some degree of pressure on their ball or nose, spring plungers keep the components in the same position. Push-fit/press-fit plungers are well-suited when threaded ball plungers are impractical due to space restrictions. Square Cam Action Spring Latches - Stainless Steel, Lock-Out, Weldable, GN 722.1Series. These locking systems designed to facilitate repetitive positioning operations on machines and equipment or parts undergoing machining.

The dimensional tolerances between latch pin and body are selected so that the functional reliability is guaranteed even after welding, applying a corrosion protection layer, or in case of contamination. If you want to free a component from the plunger's fixed position, you only have to pull the device's handle. By exerting some degree of pressure on their ball or nose, spring plungers keep the components in the same position. Push-fit/press-fit plungers are well-suited when threaded ball plungers are impractical due to space restrictions. Square Cam Action Spring Latches - Stainless Steel, Lock-Out, Weldable, GN 722.1Series. These locking systems designed to facilitate repetitive positioning operations on machines and equipment or parts undergoing machining.

Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates. The plastic ribbed sleeve offers an aesthetically pleasing and comfortable finger grip. As the contact force puts pressure on the plunger or nose of the spring plunger, it depresses in to the body forcing the internal spring to compress allowing the contact force to position the nose into the desired notched out area. Indexing Plungers - Stainless Steel, Non Lock-Out/Lock-Out with Removable Pin, GN 817.8 Series. Plot No. Strong-enough side loads will force the plungers on devices equipped with rounded noses to retract. At norelem centring clamps with ball and hexagon segments or with wedges are available. To lock the plunger's tip into the desired position, simply release the ring. The wrench flats on the lock nut are exposed when the pin is retracted, so that the plunger can be easily tightened by means of an open end wrench. fastening and joining of parts and workpieces. The wrench flats on the lock nut are exposed when the pin is retracted, so that the plunger can be easily tightened by means of an open end wrench. Standard parts and machine elements can be fixed in a certain position using indexing plungers. Locking pins are used for quick fixing, connecting and locking of various parts and workpieces. Stubby plungers are used to stabilize, position and secure seat backs and tray tables on airliners. Mandrel collets are also available for holding in bores. With this extensive range, the right standard part for interlocking is always available for practically every type of application. As the name suggests, pull-pin spring plungers have a quick-release press-fit pull-pin body. You can use pull-pin spring plungers to retract and engage the plunger for locating, fastening quickly, and quick change operations. As sprung element, a ball or pin can be selected which are available in steel, stainless steel, ceramic or polyoxymethylene (POM). Vliers push-fit/press-fit plungers come with a plunger or ball nose and provide a quick, efficient installation process that saves time and cost. Standard spring plungers are used as a detent pin for fuel injection and weapon subsystems. Standard spring plungers are often used on cabin interiors. Along with a wide range of locating pins, norelem also offers additional positioning elements including centring pins, positioning pins or locating bushes. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. After retracting the plunger pin, turn the knob 30 degrees, release the knob and it will stay in the retracted position via the indexing lock. VILLCASE 3 PCS Plunger Latches Spring- Plunger Latches Spring- loaded Plunger Latches spring loaded locking pin Baby Bed Fastening, SBDs 'POP' Pull Pin | 1/2" Diameter Spring Loaded Plunger |1" Diameter x 1-1/2" Length Weld ON Steel Barrel | Hard Plastic T Handle Knob | Knurled Round Nut, heyous Push Fit Ball Nose Spring Plunger Stainless Steel Spring Return Knob Plunger Spring Indexing Plunger M10, GN 717-NI Series Stainless Steel Lock-Out Type Inch Size Indexing Plunger with Pull Knob, with Lock Nut, 3/8"-16 Thread Size, 0.63" Thread Length, GN 717-NI Series Stainless Steel Lock-Out Type Inch Size Indexing Plunger with Pull Knob, Without Lock Nut, 5/8"-11 Thread Size, 0.94" Thread Length, WN 717.10 Series Stainless Steel Non Lock-Out Type Stubby Hand Retractable Spring Plunger with Pull Ring, 3/8"-16 Thread, 0.44" Thread Length, LRSP Series Steel Lock-Out Type Hand Retractable Spring Plunger with Knurled Handle, Without Patch, 1/4"-20 Thread Size, 0.500" Thread Length, GN 722.2 Series Steel Type A Metric Size Square Spring Latches with Flange for Surface Mounting, Latch Position Right-Angled to Mounting Holes, Zinc Plated Finish, 10mm Item Diameter, 68mm Item Length, LRSP Series Steel Lock-Out Type Hand Retractable Spring Plunger with Knurled Handle, Without Patch, 3/8"-16 Thread Size, 0.750" Thread Length, J.W. Summary. Winco's range is very wide to cover many applications. Due to their versatility, spring-loaded plungers are commonly found in a host of industries, including defense, aerospace and automotive. Where defined bores are available for engaging the integrated pin, the positive connection typical of a pin is used. Compact indexing plunger. When you need to align, hold, or latch different parts of equipment together, you need a spring loaded device. Ball plungers are commonly used for notching and indexing where they are released with predetermined side loads.

Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates. The plastic ribbed sleeve offers an aesthetically pleasing and comfortable finger grip. As the contact force puts pressure on the plunger or nose of the spring plunger, it depresses in to the body forcing the internal spring to compress allowing the contact force to position the nose into the desired notched out area. Indexing Plungers - Stainless Steel, Non Lock-Out/Lock-Out with Removable Pin, GN 817.8 Series. Plot No. Strong-enough side loads will force the plungers on devices equipped with rounded noses to retract. At norelem centring clamps with ball and hexagon segments or with wedges are available. To lock the plunger's tip into the desired position, simply release the ring. The wrench flats on the lock nut are exposed when the pin is retracted, so that the plunger can be easily tightened by means of an open end wrench. fastening and joining of parts and workpieces. The wrench flats on the lock nut are exposed when the pin is retracted, so that the plunger can be easily tightened by means of an open end wrench. Standard parts and machine elements can be fixed in a certain position using indexing plungers. Locking pins are used for quick fixing, connecting and locking of various parts and workpieces. Stubby plungers are used to stabilize, position and secure seat backs and tray tables on airliners. Mandrel collets are also available for holding in bores. With this extensive range, the right standard part for interlocking is always available for practically every type of application. As the name suggests, pull-pin spring plungers have a quick-release press-fit pull-pin body. You can use pull-pin spring plungers to retract and engage the plunger for locating, fastening quickly, and quick change operations. As sprung element, a ball or pin can be selected which are available in steel, stainless steel, ceramic or polyoxymethylene (POM). Vliers push-fit/press-fit plungers come with a plunger or ball nose and provide a quick, efficient installation process that saves time and cost. Standard spring plungers are used as a detent pin for fuel injection and weapon subsystems. Standard spring plungers are often used on cabin interiors. Along with a wide range of locating pins, norelem also offers additional positioning elements including centring pins, positioning pins or locating bushes. Indexing, spring and ball plungers and their accessories are also referred to as: spring loaded devices, detent pins, hand retractable pins, spring loaded pins, button handle pins, shackle pins, locating pins, indexing pins, retracting pins, spring loaded pins, receptacles and lanyards, rapid release pins, t-handle release pins, ball chains, self-locking rapid release pins, side thrust pins, thrust pins, spring loaded shells, ball buttons, spring loaded positioning elements, hand retractable spring plungers, lock-out spring plungers, non lock-out plungers, and spacer bushings. After retracting the plunger pin, turn the knob 30 degrees, release the knob and it will stay in the retracted position via the indexing lock. VILLCASE 3 PCS Plunger Latches Spring- Plunger Latches Spring- loaded Plunger Latches spring loaded locking pin Baby Bed Fastening, SBDs 'POP' Pull Pin | 1/2" Diameter Spring Loaded Plunger |1" Diameter x 1-1/2" Length Weld ON Steel Barrel | Hard Plastic T Handle Knob | Knurled Round Nut, heyous Push Fit Ball Nose Spring Plunger Stainless Steel Spring Return Knob Plunger Spring Indexing Plunger M10, GN 717-NI Series Stainless Steel Lock-Out Type Inch Size Indexing Plunger with Pull Knob, with Lock Nut, 3/8"-16 Thread Size, 0.63" Thread Length, GN 717-NI Series Stainless Steel Lock-Out Type Inch Size Indexing Plunger with Pull Knob, Without Lock Nut, 5/8"-11 Thread Size, 0.94" Thread Length, WN 717.10 Series Stainless Steel Non Lock-Out Type Stubby Hand Retractable Spring Plunger with Pull Ring, 3/8"-16 Thread, 0.44" Thread Length, LRSP Series Steel Lock-Out Type Hand Retractable Spring Plunger with Knurled Handle, Without Patch, 1/4"-20 Thread Size, 0.500" Thread Length, GN 722.2 Series Steel Type A Metric Size Square Spring Latches with Flange for Surface Mounting, Latch Position Right-Angled to Mounting Holes, Zinc Plated Finish, 10mm Item Diameter, 68mm Item Length, LRSP Series Steel Lock-Out Type Hand Retractable Spring Plunger with Knurled Handle, Without Patch, 3/8"-16 Thread Size, 0.750" Thread Length, J.W. Summary. Winco's range is very wide to cover many applications. Due to their versatility, spring-loaded plungers are commonly found in a host of industries, including defense, aerospace and automotive. Where defined bores are available for engaging the integrated pin, the positive connection typical of a pin is used. Compact indexing plunger. When you need to align, hold, or latch different parts of equipment together, you need a spring loaded device. Ball plungers are commonly used for notching and indexing where they are released with predetermined side loads.  For example, they are routinely used in commercial and military aircraft. Winco offers a comprehensive range of pins. Cycle life depends on the design of the plunger and the environment. Spring-loaded devices are commonly used in applications that require positioning and securing, indexing, locating, quick disconnects and ejecting, positive locking, latching and more. A ball lock pin is composed of three main components: the grip with push button, a pin and the balls. This site requires you to register or login to post a comment. You can use them as shock absorbers or ejectors by applying accurate and repeatable spring end forces through a ball or rounded nose, especially in sheet metalworking. You should also consider the force of a spring-loaded device as part of your purchasing criteria that is, whether it exerts light, standard, or heavy end-force on equipment. This way, the spring plunger can lock a component into a specific placement. Type C offers a lock-out position for applications that require the plunger pin to be retracted for an extended period of time. SBDs (Pack of 4) 'POP' Pull Pin 1" Diameter x 1-1/2" Length Weld ON Steel Barrel | 1/2" Diameter Spring Loaded Zinc Plated Steel Plunger | Plastic T Handle Knob | Knurled Round Nut w/Grub Screw Lock. This is termed a cycle. Copyright MISUMI Corporation All Rights Reserved. Pull spring plungers are best for adjustable tubing, tooling, latches, fixtures, gates, and similar equipment.

For example, they are routinely used in commercial and military aircraft. Winco offers a comprehensive range of pins. Cycle life depends on the design of the plunger and the environment. Spring-loaded devices are commonly used in applications that require positioning and securing, indexing, locating, quick disconnects and ejecting, positive locking, latching and more. A ball lock pin is composed of three main components: the grip with push button, a pin and the balls. This site requires you to register or login to post a comment. You can use them as shock absorbers or ejectors by applying accurate and repeatable spring end forces through a ball or rounded nose, especially in sheet metalworking. You should also consider the force of a spring-loaded device as part of your purchasing criteria that is, whether it exerts light, standard, or heavy end-force on equipment. This way, the spring plunger can lock a component into a specific placement. Type C offers a lock-out position for applications that require the plunger pin to be retracted for an extended period of time. SBDs (Pack of 4) 'POP' Pull Pin 1" Diameter x 1-1/2" Length Weld ON Steel Barrel | 1/2" Diameter Spring Loaded Zinc Plated Steel Plunger | Plastic T Handle Knob | Knurled Round Nut w/Grub Screw Lock. This is termed a cycle. Copyright MISUMI Corporation All Rights Reserved. Pull spring plungers are best for adjustable tubing, tooling, latches, fixtures, gates, and similar equipment.  How do spring plungers work? This product family includes the following positioning elements: Lateral spring plungers are used to position, clamp, hold or secure workpieces and components. In the resting position, or full travel position, the plunger is extended. 2. Our service team is available from Monday to Friday between 7:30 AM and 5:00 PM Central Time. Leading manufacturers of spring-loaded plungers continue to explore new materials and designs that lend themselves to new manufacturing processes and creating parts for different industries, including IIoT. Each provides different benefits. They are used in fixtures and machine tools, e.g. At this stage, you should ask questions like, What is the installation process for this plunger? What is the plungers thread length and thread size? and what can this device do?. You can also use these devices as some form of support between objects or to eject a component from its groove. Pressing the spring-loaded push button unlocks both balls, and releasing it locks the balls again. It can be pushed back into the body of the device when force on the plunger exceeds the spring force being applied. Your recently viewed items and featured recommendations, Select the department you want to search in. On the other hand, a spring lever is a mechanical tool that allows you to fix a component into a specific position. When the cam action indexing plungers are positioned symmetrically, the left or right-handed types allow for a practical, i.e. After welding, the indexing plunger is then assembled. For one, they can serve as some type of cushion between two objects. This type of plunger allows for swift one-handed operations. Before purchasing any type of spring plunger, you should ensure that it is suitable for your equipment. Spring-loaded devices will continue to help companies bring products to market faster and with more reliable performance and added functions. Press Fit Spring Plungers GN 822.1 Mini Indexing Plungers Steel, Lock-Out and Non Lock-Out, with Open Lock Mechanism. These types of spring plungers are made from steel, thermoplastic, technopolymer, or stainless steel. By your continued use of this site you accept such use. Stubby plungers are more compact, making them a good choice for applications with limited space. This in turn allows for a little space between two objects. Pull Pin Spring Plungers Spring plungers can also be used as a form of cushion between two objects. JW Winco has its own in-house machining facility; this provides an advantage for our customers to take an idea and create a unique customized solution through the choice of using one of our standard parts. They are designed for installation in thin walled sheet metal applications. GN 413 indexing plungers, due to its shape, the pull ring can be used both as a screw-in aid during assembly, and to retract the plunger pin for positioning or locking the pin in the retracted position(Type C / CK).Lock-out types C / CK are used for applications where the plunger pin needs to stay in its retracted position. Ball Plungers have no knob and a ball instead of a nose. Side loadings are used to activate spring-loaded devices in indexing, positioning and detenting operations. Type B is non lock-out type.